Reading Model Kit Quality From First Glance

Ever picked up a model kit at the shop and wondered if you're getting your money's worth? We've seen thousands of builders at Hearns struggle with this exact question. The thing is, you can actually tell heaps about a kit's quality before you even crack it open - if you know what to look for.

After three decades of helping Australian modellers choose their next project, we've learned the telltale signs that separate premium plastic kits from the dodgy ones. It's not just about brand names or price tags either. Sometimes a budget kit surprises you with crisp moulding, while an expensive one disappoints with flash and sink marks.

The real trick is understanding what different plastics tell you about the engineering behind a kit. That slightly bluish tinge on Tamiya sprues? That's their signature ABS blend. The almost glass-like clarity of modern Bandai parts? That's precision polystyrene at work. Each material has its quirks, and knowing them saves you from nasty surprises halfway through a build.

Today we're pulling back the curtain on what really matters when assessing kit quality. From sprue inspection techniques to understanding why some plastics feel "cheap" while others scream quality, this guide covers everything we wish someone had told us years ago. Whether you're eyeing up that new aircraft kit or finally tackling that Gundam on your wishlist, you'll know exactly what you're getting into.

Table of Contents

Visual Inspection Fundamentals

First impressions matter, especially with model kits. Before you even think about glue or paint, that initial look at the sprues tells you almost everything. We reckon about 80% of quality issues can be spotted in the first minute - if you know where to look.

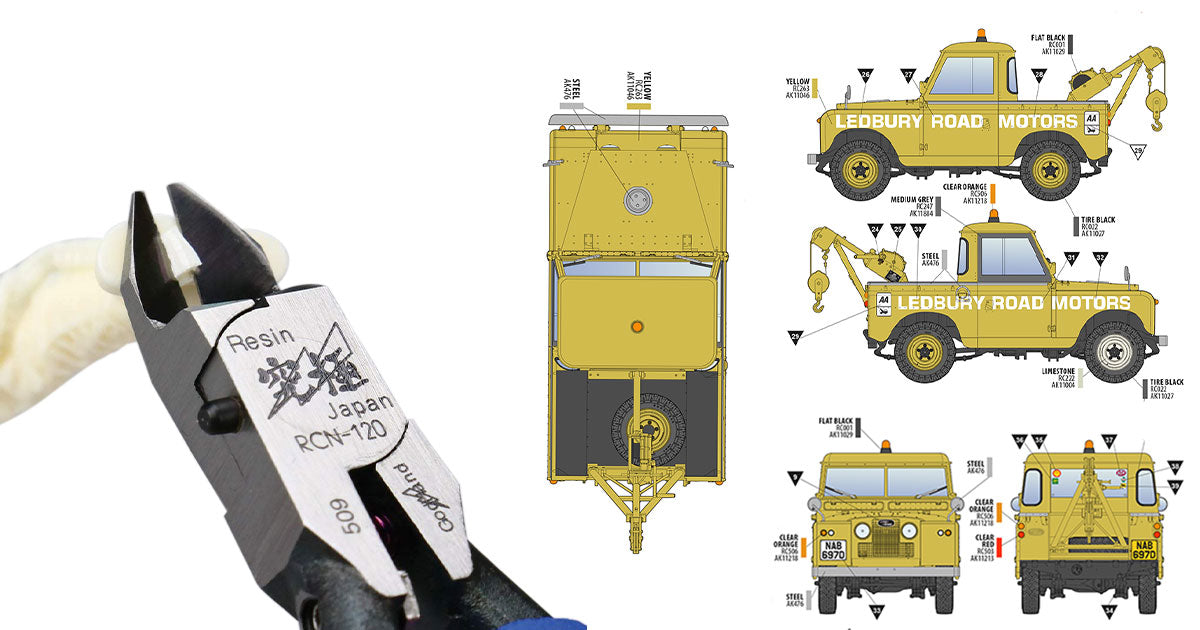

Start with the sprue gates - those connection points where parts attach to the frame. Quality kits have gates positioned thoughtfully, usually on hidden surfaces or edges that'll be sanded anyway. Cheap kits? They'll slap gates right on visible surfaces, leaving you with cleanup nightmares. Godhand nippers help, but they can't work miracles on poorly placed gates.

Next, check the surface finish under good lighting. Hold the sprue at an angle and look for that consistent sheen. Premium kits have an even, almost satiny finish that catches light uniformly. Budget kits often show swirl marks, rough patches, or that telltale "orange peel" texture that screams corner-cutting. It's especially obvious on large flat surfaces like aircraft fuselages or car bodies.

The real giveaway though? Panel line definition. Run your finger gently across the surface details. Sharp, crisp panel lines that feel consistent indicate fresh moulds and quality control. Soft, mushy details suggest worn tooling or rushed production. This is why veteran builders often prefer first-run kits - the moulds are fresh and every detail pops perfectly.

![[SUGGESTED IMAGE: Close-up comparison of high-quality vs low-quality sprue gates and surface finish on model kit parts]](https://www.hearnshobbies.com/cdn/shop/products/gh-rcn-120-r-tum1r.jpg?v=1735971761&width=350)

Understanding Different Plastic Types

Not all plastics are created equal, and each type brings its own personality to the workbench. Understanding these differences transforms how you approach each kit. Let's break down what you're actually working with when you open that box.

Polystyrene (PS) dominates the hobby world for good reason. It's the goldilocks of model plastics - cuts cleanly, glues perfectly with thin cement, and takes paint beautifully. Most Airfix and Revell kits use standard PS. You'll know it by its slight brittleness and the way it produces those satisfying white stress marks when you flex it. Quality PS feels dense and solid, while cheap stuff feels hollow and bendy.

ABS plastic plays by different rules entirely. Tougher and more flexible than PS, it's the go-to for snap-fit kits and anything needing durability. The downside? Standard plastic cement won't touch it - you need special ABS cement or CA glue. ABS feels different too, with a slightly waxy texture and more flex. It's brilliant for moving parts but can be a pain for seamless construction.

Then there's the exotic stuff. Resin kits offer incredible detail but require completely different techniques. Polyethylene (PE) shows up in flexible tracks and won't glue with anything except CA. Some Japanese manufacturers mix materials - PS for the main parts, ABS for joints, PE for flexible bits. Smart engineering, but you need to know what you're dealing with or you'll be wondering why your glue won't work.

Quick Material Test

Not sure what plastic you're dealing with? Try the float test. Drop a small piece in water - PS sinks, PE floats. Or do the bend test - PS snaps cleanly, ABS bends and returns, cheap vinyl tears. These simple tests save you from glue disasters later.

Moulding Quality Indicators

Moulding quality separates the wheat from the chaff in model kits. It's where manufacturer investment really shows, and once you know the signs, you can't unsee them. Premium kits showcase engineering that makes building a joy rather than a chore.

Flash - that thin film of excess plastic along seam lines - tells you everything about mould maintenance. New, well-maintained moulds produce parts with zero flash. As moulds wear or when manufacturers rush production, flash appears. A bit along parting lines? Normal. Flash obscuring detail or creating cleanup nightmares? That's corner-cutting. Japanese kits like Hasegawa rarely show flash because they retire moulds before quality suffers.

Sink marks reveal injection pressure problems. Look for slight depressions on flat surfaces, especially opposite thick details on the reverse side. Quality manufacturers design around this with clever part breakdown or internal bracing. Cheap kits? They just hope you won't notice that divot in the middle of your tank's turret.

Ejector pin marks deserve special attention. Every injection-moulded part needs ejector pins to pop it from the mould, but placement matters. Premium kits hide these marks on internal surfaces or incorporate them into surface detail. Budget kits scatter them everywhere - right on visible panels, across delicate details, even on clear parts. Nothing ruins a canopy faster than ejector marks you can't remove.

Part fit represents the ultimate quality test. Dry-fit major components before committing. Premium kits click together with satisfying precision - panels align, gaps stay consistent, tabs find slots naturally. Poor moulding shows as warped parts, inconsistent gaps, and that frustrating need to force things together. When you're constantly fighting fit issues, that bargain kit stops looking so good.

Moulding Defect Severity Guide

| Defect Type | Minor (Acceptable) | Major (Red Flag) |

|---|---|---|

| Flash | Thin line along seams | Thick webs, detail obscured |

| Sink Marks | Slight on hidden areas | Visible on main surfaces |

| Ejector Marks | Inside surfaces only | On visible panels/details |

| Part Warp | Slight, easily corrected | Major distortion |

Material-Specific Handling Techniques

Each plastic type demands its own approach. What works brilliantly on polystyrene might destroy ABS, and techniques perfect for resin could melt standard plastic. Getting this right makes the difference between smooth building and endless frustration.

Polystyrene loves sharp tools and responds beautifully to standard techniques. Cut with confidence using quality side cutters, leaving a small nub for cleanup. Sand with progressively finer grits - 400 for rough shaping, 800 for smoothing, 1200 for final finish. PS melts perfectly with thin cement, creating strong joints that sand seamlessly. Just remember it's brittle when cold - warm those parts to room temperature in winter or they'll snap.

ABS requires a gentler touch despite being tougher. It cuts differently, producing stringy waste rather than clean chips. Use fresh blades and cut in multiple passes rather than forcing through. Sanding generates more heat with ABS, so work slowly or the plastic gets gummy. For assembly, forget standard cement - you need ABS-specific glue or CA adhesive. The upside? ABS flexes without breaking, perfect for poseable kits.

Clear parts need special care regardless of material. Never use plastic cement near them - the vapours fog clear plastic instantly. Instead, use white glue, canopy glue, or careful CA application. Mask before painting and handle with cotton gloves to avoid fingerprints. Polish scratches with progressive grits up to 12000, then use plastic polish for crystal clarity. Some builders dip clear parts in Future floor polish for extra shine.

Soft plastics like vinyl or PE won't take conventional assembly methods. Preparation is key - wash thoroughly to remove mould release, then prime with adhesion promoter. Only CA glue or specialty vinyl adhesives work. Paint needs flexibility too - acrylics crack, so use vinyl-specific paints or add flex agents. These materials excel for figures and tracks but test everything first.

![[SUGGESTED IMAGE: Demonstration of proper cutting and sanding techniques for different plastic types, showing tools and results]](https://www.hearnshobbies.com/cdn/shop/products/GHKS5KB.jpg?v=1735246409&width=600)

Brand-Specific Quality Signatures

Every manufacturer has their signature approach to kit engineering. After handling thousands of kits, we can often identify the brand just from the plastic feel and moulding style. Understanding these characteristics helps you know what to expect before purchase.

Tamiya sets the gold standard with their consistent quality. Their plastic has a distinctive feel - slightly softer than others but incredibly consistent. Parts literally fall off the sprues with minimal cleanup. Panel lines are recessed and scaled perfectly. Even their instruction manuals showcase Japanese attention to detail. Yes, you pay more, but you're buying peace of mind. Their aircraft and armour kits especially showcase this quality.

Airfix has undergone a quality revolution. Their new-tool kits rival anyone's, with crisp moulding and thoughtful engineering. The plastic feels harder than Tamiya's but takes detail beautifully. Older Airfix kits (pre-2008) show their age with raised panel lines and basic detail, but recent releases like their new Spitfires compete with anyone. They've learned that British modellers demand quality.

Eastern European manufacturers like MiniArt bring different strengths. Their plastic tends toward the harder side, requiring sharp tools, but the detail density is insane. They'll give you individual bolt heads where others use raised bumps. The trade-off? Complex builds with hundreds of parts. Perfect for detail fanatics, potentially overwhelming for casual builders.

Chinese manufacturers show increasing sophistication. Trumpeter started rough but now produces impressive kits at competitive prices. Their plastic quality varies by production run, so checking reviews helps. Budget brands use softer plastic that's forgiving but lacks crisp detail. They're getting better though - competition drives improvement across the industry.

Brand Evolution Note

Manufacturers constantly evolve. Today's budget brand might be tomorrow's quality leader. Always check when a kit was tooled - a 2020 offering from any brand likely outperforms a premium kit from 2000. New CAD technology and manufacturing precision benefit everyone.

Common Defects and Red Flags

Some defects scream "avoid this kit" while others just need minor fixing. Knowing the difference saves money and frustration. Here's what sends kits back to the shelf and what's actually workable.

Short shots - where plastic doesn't fill the mould completely - are deal breakers. You'll see missing sections, incomplete details, or thin spots that break during assembly. No amount of putty fixes a part that's fundamentally incomplete. Check sprues carefully for parts that look "melted" or incomplete, especially thin sections like aircraft antennae or gun barrels.

Warpage hits large parts worst. Hold flat pieces against a ruler - any bow or twist shows immediately. Minor warpage fixes with hot water reshaping or careful clamping during assembly. But severe warpage, especially on main components like fuselages or ship hulls? That's hours of frustration waiting to happen. Wings that won't align or hulls that rock on flat surfaces rarely build into satisfying models.

Mould shift creates double images where mould halves don't align perfectly. Mild shift just needs cleanup, but severe cases ruin surface detail. Check circular parts especially - wheels, propellers, and engine fronts show misalignment instantly. When detail appears "drunk" or panel lines don't match across seams, you're looking at worn tooling or poor quality control.

Missing or damaged parts happen even with quality brands, but frequency tells you about QC standards. One missing part in a complex kit? Contact customer service. Multiple damaged sprues or missing runners? That's systematic failure. Always inventory against instructions before starting. Some shops let you check contents before purchase - take that opportunity with expensive or limited kits.

Fixable Issues

- • Minor flash

- • Small sink marks

- • Slight warpage

- • Poor sprue placement

- • Light mold seams

Deal Breakers

- • Short shots

- • Severe warpage

- • Major mould shift

- • Widespread damage

- • Missing major parts

Price vs Quality Reality Check

Let's bust some myths about kit pricing. Expensive doesn't always mean better, and budget doesn't automatically mean bad. Understanding what drives pricing helps you spot genuine value versus marketing markup.

Tooling costs dominate kit pricing. New moulds cost hundreds of thousands of dollars, so recent toolings carry premium prices to recoup investment. That's why a new-tool Bandai kit costs more than a rebox of 1970s moulds. But here's the thing - new tooling usually means better engineering, finer detail, and superior fit. You're paying for decades of manufacturing advancement.

Subject matter affects pricing oddly. Popular subjects like Spitfires or Tiger tanks get reboxed endlessly, driving prices down through competition. Obscure subjects might cost more despite simpler engineering because production runs stay small. That's why a basic Eastern Front vehicle might cost more than a complex Mustang.

Brand premium is real but varies by quality consistency. Tamiya commands higher prices because buyers know exactly what they're getting. Lesser-known brands offer bargains but require research. Sometimes that Czech manufacturer nobody's heard of produces gems at half the price of established brands. Reviews and building forums reveal these hidden treasures.

The sweet spot? Mid-range kits from quality-focused manufacturers. Airfix's new tools, Italeri's recent releases, and Academy's latest offerings deliver 90% of premium quality at 60% of the price. Unless you need absolute perfection for competition, these kits offer outstanding value. Save premium prices for subjects you really love or landmark kits in your collection.

![[SUGGESTED IMAGE: Price comparison chart showing different kit quality levels with example products from various manufacturers]](https://www.hearnshobbies.com/cdn/shop/files/AK35014_380a90fe-c60c-4fc4-b3b3-de851ffd56c1.png?v=1751510491&width=1200)

Building Tips for Each Material Type

Right techniques for the right material transform building from struggle to satisfaction. These tips come from years of experience and plenty of mistakes - learn from our stuff-ups rather than making your own.

Standard polystyrene responds best to patience and proper tools. Invest in quality sprue cutters - they pay for themselves in clean cuts and reduced cleanup. Cut away from the part, leaving a small nub, then trim flush with a sharp blade. Sand with the shape, not against it. For assembly, thin cement works magic - brush it along joints and capillary action does the rest. Give joints 24 hours before stressing them, despite what fast-setting claims promise.

ABS demands different tactics entirely. Because standard cement won't work, perfect fit becomes crucial. Test fit obsessively and sand mating surfaces for maximum contact. CA glue sets fast, so no second chances - get alignment right first time. For large assemblies, use accelerator spray sparingly. ABS sands differently too, loading paper quickly. Use wet sanding or frequently clean your abrasives. The material's flexibility means you can bend parts slightly for better fit - just don't overdo it.

Mixed-media kits test all your skills. Map out which parts use what material before starting. Nothing worse than melting an ABS part with PS cement or wondering why your PE tracks won't stick. Keep adhesives organized and labeled. Build in subassemblies grouped by material type. This prevents cross-contamination and lets you use optimal techniques for each material.

Problem plastics need creative solutions. Brittle old plastic benefits from annealing - gentle heating to relieve stress. Soft vinyl parts shape better when warmed in hot (not boiling) water. Resin parts always need washing to remove mould release. When plastics won't cooperate, sometimes switching adhesives helps - try epoxy for stubborn joints or white glue for clear parts. The key is testing on hidden areas first.

Universal Building Truth

Regardless of material, dry fitting saves disasters. Every joint, every assembly, every major component - test fit before gluing. Mark alignment points with pencil. Pre-paint sub-assemblies where possible. These simple habits prevent those "oh no" moments when parts won't fit after painting or when you realize something's backwards after the glue sets.

Frequently Asked Questions

How can I tell if an old kit is still worth building despite its age?

Check the sprue condition first - brittleness and discolouration indicate degraded plastic that might shatter during assembly. Gently flex a hidden runner section - good plastic returns to shape, degraded plastic whitens or cracks. Look for mould quality rather than age - some 1980s Tamiya moulds still produce better parts than modern budget kits. If decals look yellowed or cracked, plan on aftermarket replacements. Classic kits often build into charming models with patience and proper techniques.

What's the best way to fix warped plastic parts without damaging them?

Hot water reshaping works brilliantly for most plastics. Submerge the warped part in water just below boiling (80-90°C) for 10-30 seconds until pliable. Gently reshape by hand or against a flat surface, then immediately plunge into cold water to set the shape. For large parts like ship hulls, use a hair dryer on low heat while applying gentle pressure. Thick parts might need multiple cycles. Never force cold plastic - it'll snap rather than bend.

Should I always choose newer toolings over classic kits?

Not necessarily. New toolings offer superior detail and fit, but classic kits have their place. Some old Airfix or Monogram kits capture subjects nobody's retooled. They build into perfectly acceptable models with basic skills. Classic kits also cost less, making them perfect for practicing techniques or conversion projects. The key is matching kit quality to your goals - competition builds demand cutting-edge toolings, while shelf displays might not need that perfection.

How do I identify counterfeit model kits?

Counterfeits plague popular brands, especially Bandai and Tamiya. Warning signs include suspiciously low prices, poor box printing with blurry images or wrong colours, missing or fake hologram stickers, and plastic that feels wrong - too soft, wrong colour, or poor surface finish. Instructions often show telltale signs too - bad English, fuzzy printing, or missing pages. Buy from reputable sources like Hearns Hobbies to avoid disappointment. If a deal seems too good, it probably is.

Final Thoughts

After helping thousands of modellers choose their perfect kit, we've learned that quality recognition is a skill worth developing. Sure, you can just grab any box that catches your eye, but understanding what you're buying transforms the entire experience. No more nasty surprises halfway through a build, no more fighting poor engineering when you should be enjoying your hobby.

The best part? Once you know these quality markers, kit selection becomes intuitive. You'll spot the telltale signs of fresh tooling versus tired moulds. You'll feel the difference between precision engineering and rushed production. Most importantly, you'll match kit quality to your project goals - saving premium prices for special builds while recognizing hidden gems among budget offerings.

Remember, even the fanciest kit needs proper handling to shine. Match your techniques to the materials, invest in decent tools, and don't rush the process. Every kit teaches you something, whether it's a premium Master Grade Gundam or a simple quick-build. The journey from sprue to finished model should be enjoyable, not a battle against poor quality.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments