Photo-Etch Parts Bending Wrong? Master the Grain Direction Fix

Ever watched a perfectly good photo-etch part snap right at the bend line? We've all been there - that sickening crack when an expensive PE detail set breaks during what should've been a simple fold. The culprit isn't your technique or tools - it's something most modelers never consider: metal grain direction.

At Hearns Hobbies, we see frustrated builders bring in broken photo-etch parts regularly. They're doing everything right - scoring properly, using the right bending tools, working slowly - yet pieces still crack or bend unevenly. Here's the thing: understanding grain direction transforms photo-etch work from a game of chance into predictable success.

Think of metal grain like wood grain. Just as timber splits easily along the grain but resists breaking across it, photo-etched brass and steel have directional properties that affect how they bend. This invisible structure determines whether your part folds cleanly or fractures. Once you understand this principle, those mystifying failures suddenly make perfect sense.

Today we're diving deep into the metallurgy behind photo-etch production and how it impacts your scale modeling projects. More importantly, we'll show you practical techniques to identify grain direction and work with it rather than against it. No more guessing, no more broken parts - just clean, professional bends every time.

Table of Contents

Understanding Metal Grain in Photo-Etch

Photo-etch parts start life as thin metal sheets - typically brass, stainless steel, or nickel silver. During manufacture, these sheets pass through rollers that compress and stretch the metal, aligning its crystalline structure in one direction. This rolling process creates what metallurgists call "grain direction" - essentially highways of aligned metal crystals that run parallel to the rolling direction.

When you bend metal perpendicular to the grain (across those crystal highways), the bend distributes stress evenly. The metal fibers support each other, creating a clean fold. But bend parallel to the grain? You're trying to separate those aligned crystals, and they'll split apart like a banana peel. This fundamental principle explains why identical-looking parts from the same fret behave so differently when bent.

Quality photo-etch manufacturers understand this and try to orient parts optimally on the fret. However, complex detail sets often require compromises - some parts must be oriented for economical fret layout rather than ideal bending direction. Eduard, Aber, and other premium brands generally do better at considering grain orientation, but even they can't always accommodate every bend.

The thickness of photo-etch also affects how grain impacts bending. Thinner materials (0.1-0.2mm) show less grain sensitivity because there's simply less material to crack. Thicker parts (0.3mm and up) demand much more attention to grain direction. This is why ship model railings often bend beautifully while aircraft landing gear doors crack - thickness amplifies grain effects.

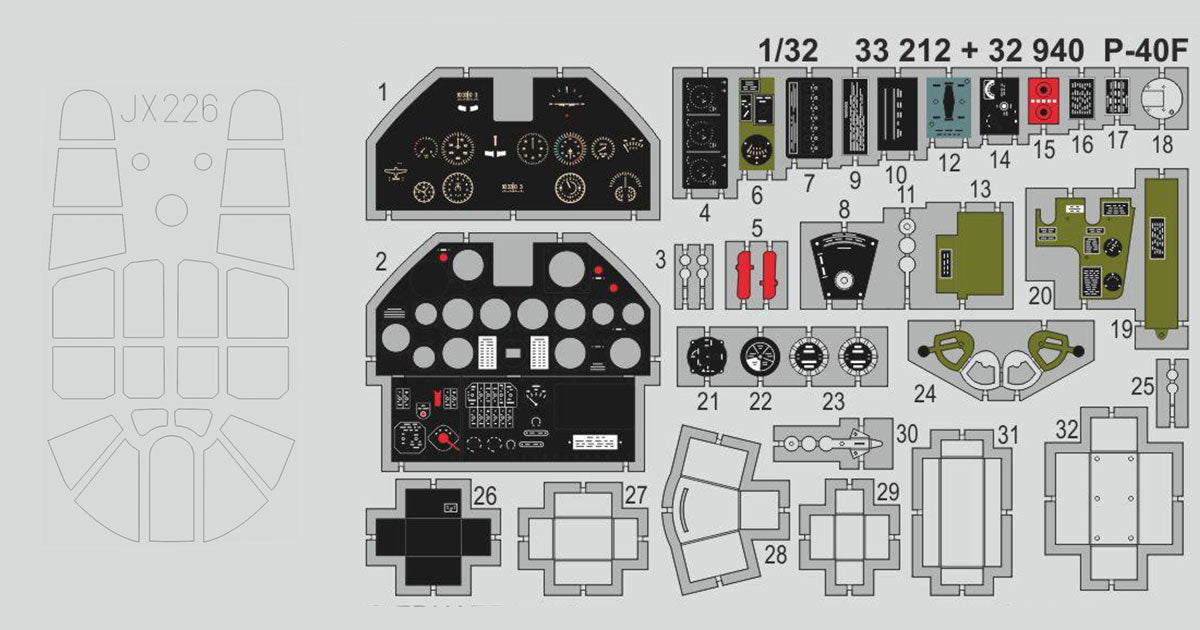

![[SUGGESTED IMAGE: Close-up microscopic view of metal grain structure in photo-etch material, showing aligned crystal patterns]](https://www.hearnshobbies.com/cdn/shop/products/33212_b1c89eac-b095-48b8-8834-4321c161739a.jpg?v=1744320793&width=500)

How to Identify Grain Direction

Spotting grain direction takes practice, but several reliable methods work across different lighting conditions. The most straightforward technique involves examining the metal surface under angled light. Grain typically appears as subtle parallel lines running along the sheet - though these can be hard to see on highly polished photo-etch.

A more reliable method uses gentle test bending. Take a spare piece from the fret edge and make tiny bends in different directions using needle-nose pliers. The direction that bends cleanest with least resistance runs perpendicular to the grain. Where you feel more resistance or see micro-cracks forming, you're bending with the grain. This destructive test on scrap pieces saves your actual parts.

Some manufacturers help by including grain indicators on their frets. Look for small arrows or marks along the fret edges - these usually indicate grain direction. Premium sets from companies like Voyager Model or Griffon Model often include grain direction notes in their instructions, though this practice remains frustratingly rare across the industry.

Visual clues on the fret itself provide hints too. Long, straight edges on the fret typically run parallel to grain direction. The way parts are arranged - especially long strips or structural pieces - often follows grain orientation for optimal bending. When multiple identical parts appear on a fret, compare their orientation; manufacturers usually keep all similar parts aligned the same way relative to grain.

Quick Test Method

Before removing parts from the fret, identify a waste area and perform a 90-degree test bend. The direction requiring least force indicates perpendicular-to-grain orientation. Mark this on your work surface with tape for reference during assembly.

Proper Bending Techniques for Different Grains

Once you've identified grain direction, adapting your bending technique makes all the difference. For bends running perpendicular to grain (the ideal scenario), standard methods work perfectly. Score lightly if needed, position your bending tool precisely at the bend line, and fold smoothly. These bends rarely cause problems when done carefully.

Parallel-to-grain bends require a completely different approach. First, anneal the bend area if possible - carefully heating the metal with a lighter until it just begins to change colour, then allowing it to cool slowly. This realigns some crystal structure and reduces cracking risk. Not all photo-etch materials respond well to annealing (stainless steel barely changes), but brass becomes noticeably more pliable.

For non-annealable parts, use the "progressive bending" technique. Instead of attempting a full 90-degree bend at once, work in stages: 30 degrees, then 60, then 90. Between each stage, gently work the bend line with a burnishing tool to compress and stabilize the metal. This gradual approach prevents the catastrophic cracks that come from forcing parallel-grain bends.

The "reverse pre-bend" method works wonders on stubborn parallel-grain folds. Gently bend the part about 10 degrees in the opposite direction first, then return it flat. This slight working of the metal helps break up the grain structure at the bend line. Now perform your actual bend - you'll find it folds more evenly with less risk of cracking. Professional modelers swear by this technique for difficult bends.

![[SUGGESTED IMAGE: Step-by-step demonstration of the progressive bending technique on a photo-etch part]](https://www.hearnshobbies.com/cdn/shop/products/HTB1WcShNgHqK1RjSZFPq6AwapXau.jpg?v=1722269027&width=700)

Common Photo-Etch Mistakes and Solutions

The biggest mistake? Assuming all photo-etch bends the same way. We see modelers who've successfully completed one PE set struggle terribly with another, simply because grain orientation differs. Each manufacturer - and sometimes each product line - has its own characteristics. What works for an Eduard set might fail spectacularly on a cheaper generic upgrade.

Over-scoring represents another frequent error. Deep score lines seem helpful but actually create weak points that encourage cracking, especially on parallel-grain bends. Light scoring - just enough to create a visible guide line - works much better. For precision, use a sharp scribing tool with minimal pressure rather than pressing hard with a dull knife.

Temperature ignorance causes plenty of failures too. Cold metal is brittle metal. During Melbourne winters, photo-etch stored in unheated sheds becomes significantly more prone to cracking. Bring parts to room temperature before working them. Conversely, avoid bending immediately after annealing - let the metal cool completely first, as hot brass is soft but also unpredictable.

Tool selection mistakes compound grain issues. Using flat-jaw pliers on small parts concentrates stress at the jaw edges, right where cracks love to start. Invest in proper photo-etch bending tools with smooth, rounded edges. The classic "Hold and Fold" tool remains popular for good reason - it distributes pressure evenly across the bend line rather than creating stress points.

Common Failure Points

| Problem | Cause | Solution |

|---|---|---|

| Crack at bend | Parallel grain bend | Anneal or progressive bend |

| Uneven fold | Grain variation | Pre-work the bend line |

| Multiple cracks | Over-scoring | Lighter score lines |

| Edge splits | Wrong tool pressure | Use proper PE tools |

Essential Tools and Setup

Proper tooling transforms photo-etch work from frustration to satisfaction. Start with a quality bending tool - the single-edge razor blade method works but lacks precision. Purpose-built PE bending tools like those from Tamiya or Master Tools provide consistent results through better leverage and control.

Your work surface matters more than you'd think. A smooth, hard surface like glass or a cutting mat provides the resistance needed for clean bends. But here's a pro tip: for delicate parts, place a sheet of paper under the PE. This slight cushioning prevents over-bending and provides just enough give to reduce cracking on difficult grain orientations.

Magnification changes everything when working with tiny parts. A basic magnifying lamp lets you see grain patterns, monitor bend progress, and spot developing cracks before they become failures. Those working with 1:700 ship railings or 1:144 aircraft details find magnification absolutely essential.

Don't overlook holding tools. Quality tweezers in various sizes give you precise control without damaging delicate parts. Avoid serrated tips that can mar soft brass - smooth or rubber-tipped tweezers work best. For repetitive bends, small smooth-jaw pliers designed for jewelry work excel at gripping without marking.

Minimum Tool Kit

Start with: PE bending tool, steel ruler, fine tweezers, smooth cutting mat, sharp hobby knife, and good lighting. This basic kit handles 90% of photo-etch work. Add specialized tools as your skills and projects demand.

Advanced Tips for Complex Parts

Multi-directional parts present unique challenges when grain runs differently than your bend requirements. Consider aircraft cockpit instrument panels with bends in multiple directions - some will inevitably go against the grain. For these, plan your bend sequence carefully. Complete perpendicular-to-grain bends first while the part remains flat and stable, then tackle the difficult parallel bends.

Compound curves demand creative solutions since photo-etch wants to bend in straight lines. For curved armor plates or aircraft cowlings, use progressive forming over round mandrels. Start with a larger diameter form and work down to your target curve. This gradual approach respects grain direction while achieving smooth curves. Brass responds beautifully to this technique; stainless steel requires more patience.

Box structures test every skill you've learned. Those tiny ammunition boxes or equipment cases combine multiple 90-degree bends in close proximity. Pre-form all bends partially before committing to final angles. This lets you adjust for spring-back and ensures corners meet properly. A tiny drop of CA glue at corners adds strength without visible bulk.

Sometimes the best solution involves redesigning the part. If a complex bend fights you due to grain orientation, consider cutting it into separate pieces and joining them. A thin bead of CA glue along a seam often looks cleaner than a cracked bend. This approach feels like cheating but produces superior results - nobody examines your model with a magnifying glass looking for extra joints.

![[SUGGESTED IMAGE: Complex photo-etch assembly showing multi-directional bends and box structures being formed]](https://www.hearnshobbies.com/cdn/shop/products/edk48483_4529a0c6-4ea7-4f32-bf53-6713460e0d6a.jpg?v=1744320785&width=1000)

Troubleshooting Difficult Bends

When a part absolutely refuses to bend cleanly despite proper technique, several rescue options remain. The "stress relief cut" method works wonders - make a tiny cut perpendicular to the bend line at each end. This relieves stress concentration and allows the middle section to bend properly. The cuts are usually invisible once painted, especially in corners or against other details.

For partially cracked bends that haven't completely failed, stabilization saves the day. Flow thin CA glue into the crack from the back side, then quickly complete the bend while the glue remains liquid. The CA reinforces the weakened metal and prevents further splitting. This fix won't win beauty contests up close but saves irreplaceable parts.

Spring-back plagues certain materials and bend angles. That perfect 90-degree fold relaxes to 85 degrees as soon as you release pressure. Combat this by slight over-bending - go to 95 degrees and let it spring back to 90. For critical angles, makeshift jigs from scrap plastic ensure consistency. Styrene strips glued at right angles create perfect forming guides.

Sometimes the problem isn't technique but the metal itself. Poor quality photo-etch uses inconsistent alloys or improper heat treatment, making clean bends nearly impossible. If an entire fret seems problematic, test thoroughly before committing to the build. Quality manufacturers like Eduard rarely have these issues, but budget sets can be wildly inconsistent. When in doubt, buy from reputable brands available at trusted suppliers.

Emergency Fixes

- • Stress relief cuts

- • CA reinforcement

- • Heat annealing

- • Part substitution

- • Gentle re-working

Prevention Tips

- • Test bend first

- • Check grain direction

- • Room temperature work

- • Proper tool selection

- • Quality PE sets

Brand Differences and What to Expect

Not all photo-etch is created equal, and understanding brand characteristics saves frustration. Eduard sets the gold standard with consistent brass alloy and logical grain orientation. Their instructions often include bending diagrams, and the metal typically anneals well. You'll pay more for Eduard, but the working properties justify the cost for complex projects.

Voyager Model produces incredibly detailed sets, but their thicker gauge material demands respect. Grain effects are more pronounced, requiring careful attention to bend direction. They excel at armor modeling details where the thickness adds realistic scale weight. Just remember - that thickness means less forgiving grain characteristics.

Generic or unbranded sets vary wildly in quality. Some work beautifully, others crack if you look at them wrong. The metal composition might change between production runs, making consistent results impossible. For critical projects or expensive ship models, stick with known brands. The few dollars saved on generic PE isn't worth ruining a months-long build.

Aber uses a slightly different brass alloy that some modelers prefer for its working properties. It's softer than Eduard but harder than typical Asian imports, hitting a sweet spot for hand forming. Their sets often include more spare parts, acknowledging that photo-etch work involves a learning curve. This thoughtful approach makes them popular with builders tackling their first serious PE projects.

Brand Selection Tip

For your first PE project, choose Eduard or Aber sets designed for your specific kit. Their fit accuracy and bending properties forgive beginner mistakes. Graduate to specialty brands once you've mastered basic techniques.

Frequently Asked Questions

Can I fix photo-etch parts that have already cracked?

Sometimes, yes. Small cracks can be stabilized with thin CA glue applied from the backside. For major breaks, consider cutting the part at the crack and joining the pieces with glue - it often looks better than a repaired crack. If the part's structurally critical, like landing gear details, replacement might be the safest option. Keep damaged parts as templates for scratch-building replacements from brass sheet.

Why do some photo-etch parts bend easily while others crack immediately?

Three factors create this variation: metal thickness, alloy composition, and grain orientation relative to your bend. Thinner parts (under 0.2mm) bend more easily regardless of grain. Different manufacturers use different brass alloys - some more ductile than others. But the biggest factor remains whether you're bending with or against the grain direction. Even premium photo-etch sets include parts oriented poorly due to fret layout constraints.

Should I anneal all photo-etch parts before bending?

No, only anneal when necessary. Most perpendicular-to-grain bends work perfectly without annealing. Reserve this technique for problematic parallel-grain bends or when re-working failed bends. Over-annealing makes brass too soft, losing the spring tension needed for clips and fasteners. Stainless steel PE barely responds to amateur annealing attempts, so don't bother unless you have proper heat-treating equipment.

What's the best way to practice before working on expensive PE sets?

Start with leftover fret frames from completed sets - they're perfect practice material. Buy an inexpensive generic PE set to develop your skills. Practice identifying grain direction, annealing, and different bending techniques. Basic brass sheets from hobby stores let you practice without the pressure of ruining kit parts. Some modelers keep a "practice box" of PE scraps specifically for testing new techniques.

Final Thoughts

Understanding grain direction transforms photo-etch from a source of frustration into a predictable, enjoyable part of modeling. We've covered the metallurgy, identification techniques, and practical solutions that'll save your sanity and your parts. The invisible grain structure in that tiny brass piece doesn't have to be your enemy - work with it, and those perfect bends become routine rather than lucky accidents.

Remember, even experienced modelers occasionally crack a part. The difference is they know why it happened and how to prevent it next time. Start with quality photo-etch sets from reputable manufacturers, invest in proper tools, and practice the techniques we've outlined. Your builds will show the difference.

Next time you're facing a complex photo-etch fret, take a moment to identify the grain before diving in. That small investment of time prevents the heartbreak of broken parts and rushed repairs. Whether you're detailing military models or adding precision to scale vehicles, understanding grain direction elevates your modeling to the next level.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments