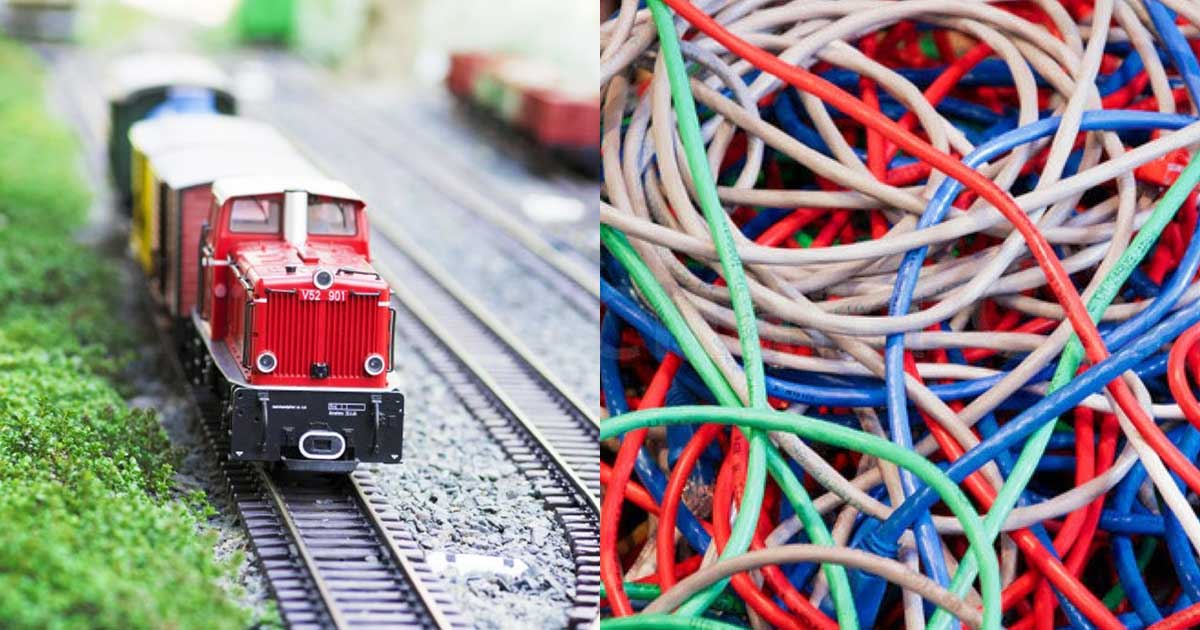

Model Railway Wiring Mistakes You Must Avoid

Master the fundamentals of railway wiring without the costly errors

In this comprehensive guide, we break down the most common—and costly—model railway wiring errors hobbyists make. More importantly, we'll show you exactly how to prevent them before they happen. We'll cover everything from using the wrong wire gauge to neglecting proper isolation sections, and even offer smart tips on choosing dependable digital control systems and power supplies that won't let you down.

You'll also find product and tool suggestions from trusted brands like DCC Concepts, Hornby, and Peco to keep your wiring clean, reliable, and future-proof. Whether you're working in HO, N scale, or something more niche, this guide will help you avoid frustration, save time, and protect your investment.

| Key Takeaways: Model Railway Wiring Mistakes | ||

|---|---|---|

| Most Common Mistake | Using incorrect wire gauge causing voltage drops | Use 16-18 AWG for bus lines |

| Biggest Time Waster | Poor wire management and labelling | Create wiring diagrams from day one |

| Most Expensive Error | Overloading controllers without protection | Install surge protectors and fuses |

| Essential Equipment | Power bus system with proper droppers | Never rely on rail joiners alone |

| Best Prevention | Regular maintenance with proper tools | Check our maintenance collection |

Quick Question: Ever wondered why your mate's layout runs smoothly while yours keeps having power issues? Nine times out of ten, it comes down to proper wiring fundamentals that were established right from the start.

Let's get your layout powered up the right way—without the headaches, frustration, or expensive mistakes that plague so many railway enthusiasts. Ready to transform your wiring from problematic to professional?

Using the Wrong Wire Gauge: The Foundation of Power Problems

Choosing the correct wire gauge is one of the most fundamental aspects of model railway wiring—and surprisingly, one of the most overlooked by enthusiasts. If your wires are too thin, you'll experience voltage drops that make locomotives crawl to a halt mid-journey. Too thick? Well, you're making life unnecessarily difficult and wasting money on copper you don't actually need.

Most hobbyists grab whatever wire they've got lying around, thinking "wire is wire, right?" Wrong. Dead wrong. For most layouts, 16–18 AWG wire suits power bus lines perfectly, while 20–22 AWG works brilliantly for dropper connections. You've got to factor in the total length of your runs and the number of connections you're planning.

Here's what happens when you get it wrong: voltage drops across long thin wires mean your locomotives receive inconsistent power. Sound decoders cut out. Lights dim. Your carefully planned DCC system starts throwing error codes because it can't maintain proper communication.

Brands like DCC Concepts provide high-quality pre-tinned wire that makes soldering infinitely easier. Pre-tinned wire flows beautifully when heated, creating strong joints that won't fail after months of layout operation. Keep a multimeter handy to check voltage consistency across your layout—you should see minimal drop from your power supply to the furthest reaches of your track.

| Wire Gauge (AWG) | Best Application | Maximum Run Length |

|---|---|---|

| 14 AWG | Main power bus for large layouts | Unlimited for model railway use |

| 16 AWG | Standard power bus | Up to 15 metres |

| 18 AWG | Medium power bus, accessory feeds | Up to 8 metres |

| 20-22 AWG | Track droppers, signal wiring | Under 1 metre |

Poor Soldering Techniques: The Weak Link in Your Chain

A bad solder joint can mean intermittent connections and hours of frustrating troubleshooting that'll drive you absolutely mental. Cold joints—where the solder hasn't properly melted and flowed—are incredibly common in rushed jobs. You know the ones: they look grey and crystalline instead of smooth and shiny.

Use a reliable soldering iron from our maintenance tools collection to ensure secure connections every time. Temperature matters enormously here. Too cool and you get cold joints. Too hot and you'll melt plastic sleepers or damage delicate decoder wiring.

Always tin your wires before soldering—this means applying a thin coat of solder to each wire end before joining them. Use flux religiously; it helps the solder flow properly and creates stronger joints. If you're soldering directly to track sections, avoid melting the plastic sleepers by working quickly and using the right temperature.

Pro Tip:

Consider using pre-drilled track accessories like copper-clad sleepers or specialised rail joiners designed for electrical connections. They make professional-grade joints without risking damage to your expensive track.

What's the biggest mistake here? Rushing. Take your time, heat the joint properly, and let the solder flow naturally. A properly made joint will last decades. A rushed one will fail when you least expect it—usually during an important operating session with visitors watching.

Skipping the Power Bus: A Recipe for Disappointment

Relying solely on rail joiners to carry current across your layout is like building a house on sand. It's unreliable, unpredictable, and guaranteed to cause problems as your layout grows. Rail joiners work loose. They corrode. They create resistance that drops voltage and ruins performance.

A proper power bus distributes electricity evenly using thick-gauge wire running beneath your baseboard, with individual droppers connecting every track section. This isn't optional for layouts larger than a simple oval—it's absolutely essential for reliable operation.

For best results, use colour-coded wire to distinguish positive and negative feeds. Red for positive, black for negative—simple and consistent. Connect each track section individually to avoid voltage drops that'll plague your rolling stock performance. Install a surge protector to safeguard your investment from power spikes that can destroy expensive electronics.

How many droppers do you need? One pair every metre is overkill for most layouts, but one pair every two metres is sensible for HO scale. N scale can stretch to three metres between droppers due to lower current requirements.

Overloading Your Controller: When More Isn't Better

Each controller has a power limit, and exceeding it leads to overheating, automatic shutdowns, and potentially permanent damage. Adding too many locomotives with sound decoders, or connecting multiple lighting accessories without upgrading your power supply is asking for trouble.

Modern sound-equipped locomotives can draw surprising amounts of current. A single sound decoder locomotive might use 0.5-1 amp during operation. Add multiple trains, plus point motors, signals, and lighting, and you'll quickly exceed basic controller capabilities.

| Controller Type | Maximum Amps | Suitable Layout Size | Typical Cost Range |

|---|---|---|---|

| Basic DC Controller | 1-2A | Small layouts, 1-2 trains | Budget-friendly |

| Entry DCC System | 2-3A | Medium layouts, multiple trains | Mid-range investment |

| Professional DCC | 5A+ | Large layouts with sound | Premium pricing |

Use a digital control system designed to scale with your layout ambitions. Systems from manufacturers like NCE offer modular expansion—you can add boosters to handle larger power draws safely without replacing your entire setup.

Wire Management: Organisation That Actually Matters

A spaghetti mess of wires beneath your baseboard will make troubleshooting an absolute nightmare. When something goes wrong—and it will—you'll spend more time tracing wires than fixing the actual problem. Proper organisation isn't about looking pretty; it's about functional maintenance.

Use cable ties, trunking, and labels religiously. Every wire should have a purpose you can identify months later. For a truly professional appearance, consider modular wiring systems with built-in terminals that make connections secure and easily changeable.

Create a wiring schematic and store a printed copy with your layout documentation. Document your point motor connections, signal wiring, and power districts. You'll thank yourself when something needs modification or repair months down the track.

Group related wires together: power feeds in one bundle, accessory decoder connections in another, signal wiring separately. Use different coloured cable ties or sleeves to distinguish between systems. This systematic approach saves countless hours during maintenance and expansion projects.

Forgetting Isolation Sections: Planning for Flexibility

Failing to isolate sections of track creates problems that multiply as your layout grows. Shorts in one area affect the entire system. Multiple trains become impossible to control independently. Debugging specific problems becomes a guessing game that wastes hours.

Use insulated rail joiners strategically to create electrical blocks. This enables you to park locomotives on sidings, run multiple trains independently, and isolate problem areas without shutting down your entire layout. Quality rail joiners from manufacturers like Peco ensure reliable isolation that won't fail over time.

Isolation isn't just about preventing shorts—it's about creating a flexible system that grows with your interests. Today's simple loop becomes tomorrow's complex layout with multiple operators and simultaneous train movements.

Plan your electrical blocks during the initial design phase, not as an afterthought. Consider where you'll want independent control: staging areas, industrial sidings, passenger platforms, and maintenance facilities all benefit from separate electrical districts.

Neglecting Tools and Maintenance: The Hidden Foundation

Electrical performance degrades without regular maintenance, full stop. Dust accumulates on rails and reduces conductivity. Oxidation forms on connections and creates resistance. Loose joints develop over time and create intermittent faults that are incredibly frustrating to diagnose.

Equip yourself with proper track cleaning equipment, quality lubricants, and diagnostic tools from our railway maintenance collection. A rolling road helps identify locomotives with poor pickup or electrical inconsistencies before they cause operating problems.

Regular check-ups prevent small issues becoming major headaches. Clean your track monthly. Check wire connections quarterly. Test your power supplies annually. This maintenance schedule keeps your layout running reliably and protects your investment in expensive electronics.

Prevention costs pennies compared to replacement. A quality track cleaning car used regularly prevents the need for deep cleaning sessions that can damage delicate detail parts on your rolling stock.

Frequently Asked Questions

What wire gauge should I use for my first DCC layout?

For most beginners, 16 AWG works brilliantly for your main power bus, with 20-22 AWG droppers connecting individual track sections. This combination handles typical HO scale layouts perfectly without breaking the bank. Avoid the temptation to use whatever wire you've got lying around—proper gauge selection prevents voltage drops that'll plague your locomotives from day one.

How many track droppers do I actually need?

One pair every two metres works well for HO scale, while N scale can stretch to three metres between connections. Never rely on rail joiners alone—they work loose, corrode, and create the intermittent faults that'll drive you absolutely mental during operating sessions. Install droppers from day one, even on small layouts.

Can I upgrade my controller later without rewiring everything?

Absolutely, provided you've installed a proper power bus system from the start. Quality DCC systems are designed for expansion—you can add boosters, upgrade command stations, and expand power capacity without touching your track wiring. Skip the power bus, and you'll be rewiring the entire layout when you inevitably outgrow your starter controller.

What's the most critical tool for troubleshooting electrical problems?

A decent multimeter is absolutely essential—it's your detective tool for tracking down voltage drops, testing continuity, and diagnosing shorts. Combine this with proper wire labelling and a circuit diagram, and you'll solve most electrical gremlins in minutes rather than hours. Quality diagnostic tools pay for themselves the first time they save you from rewiring a section.

How do I prevent short circuits from shutting down my entire layout?

Install electrical isolation between different track sections using insulated rail joiners. This creates separate power districts that can be individually controlled and isolated when problems occur. A derailment in the goods yard won't shut down your main line, and you can park locomotives on isolated sidings without affecting other operations. Plan these districts during initial construction—retrofitting isolation is far more work than doing it right the first time.

Conclusion

Getting your model railway wiring right from the start transforms your hobby experience from frustrating troubleshooting sessions to smooth, reliable operation. The mistakes we've covered—wrong wire gauges, poor soldering, skipping power buses, overloading controllers—are completely avoidable with proper planning and quality components from trusted manufacturers like DCC Concepts, Hornby, and Peco.

Remember, electrical infrastructure isn't the glamorous part of the hobby, but it's absolutely fundamental to everything else you'll build. Spend time on proper wire management, invest in quality power supplies and control systems, and create systematic isolation districts. Your future self will thank you when expansions are straightforward additions rather than complete rewiring projects.

Final Thoughts:

Whether you're planning your first oval or expanding an existing empire, solid electrical foundations make everything else possible. Take the time to do it properly, use quality components, and maintain your system regularly. The reward? Years of reliable operation that lets you focus on the fun stuff—running trains, not chasing electrical gremlins. Check our complete range of wiring and power solutions to get your layout powered up the professional way.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments