Vintage RC Care: Preserving Your Classic Remote Control Treasures

Expert maintenance tips to keep your nostalgic machines running smoothly for decades

At Hearns Hobbies, we've seen countless enthusiasts struggling to properly care for their beloved oldies. Whether your vintage RC is a displayed shelf queen or still tears up the backyard on weekends, proper maintenance is absolutely essential for keeping these classic machines in top nick for years to come.

In this comprehensive guide, we'll walk you through everything you need to know about looking after your vintage RC cars, buggies, and trucks. From the best RC tools to have on hand, to the right cleaning techniques that won't damage those decades-old plastics. We'll cover lubrication secrets, electrical maintenance, and even proper storage methods that'll preserve both performance and collectible value.

| Vintage RC Care at a Glance | |

|---|---|

| Key Care Areas | Cleaning, lubrication, component inspection, battery maintenance, proper storage |

| Must-Have Tools | Precision screwdrivers, soft brushes, specialised RC tools, microfibre cloths |

| Common Problems | Brittle plastics, corroded electronics, degraded tyres, seized bearings |

| Preservation Goals | Maintain originality, prevent deterioration, ensure safe operation, preserve collector value |

What Makes Vintage RCs Special

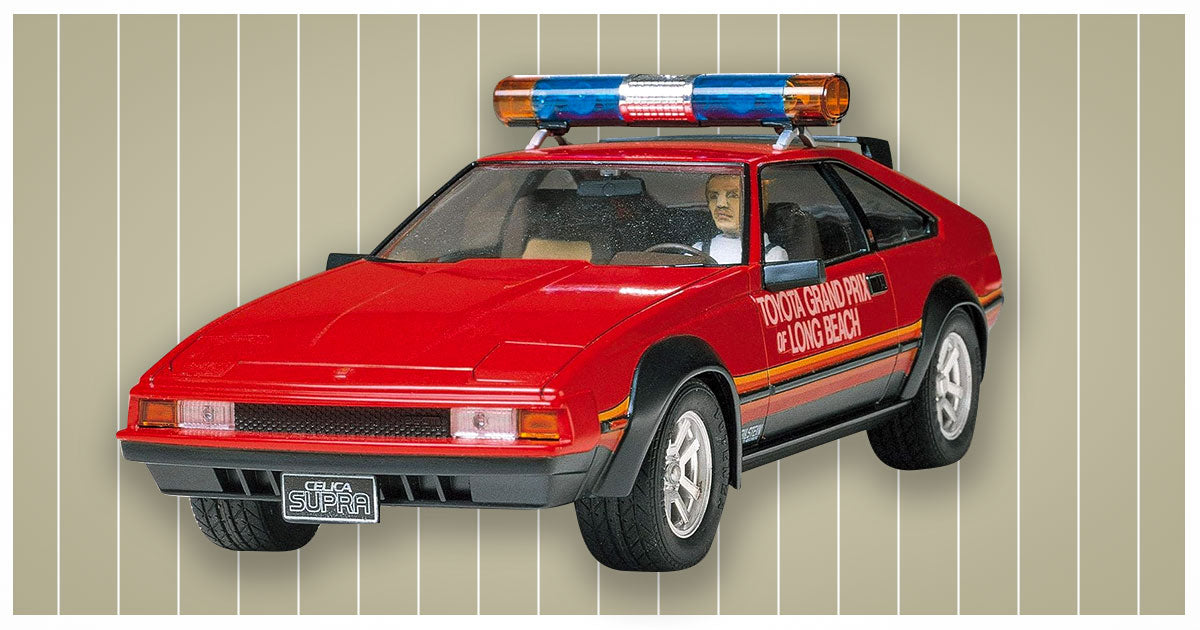

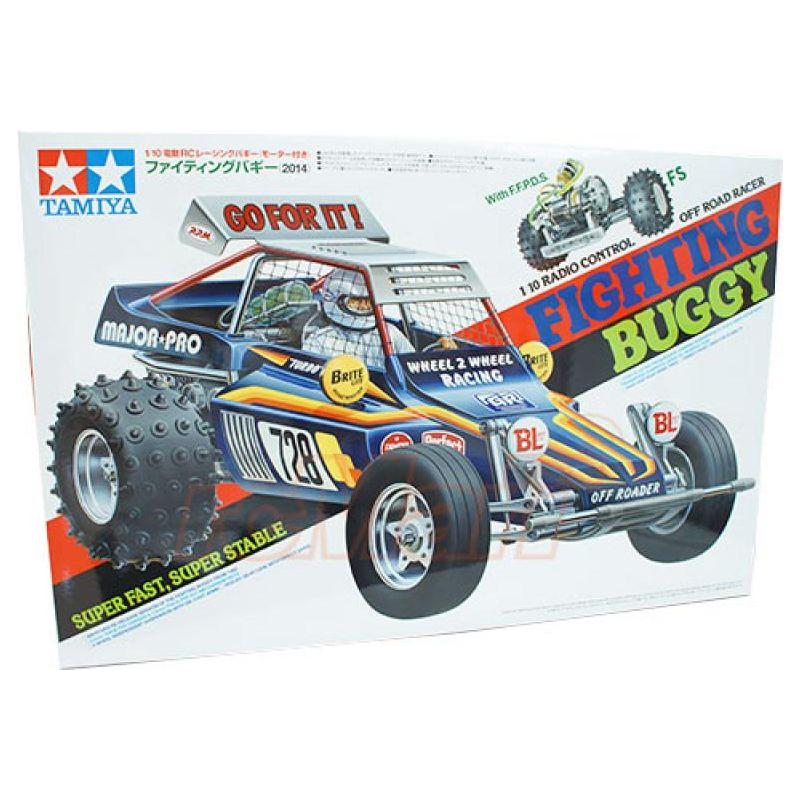

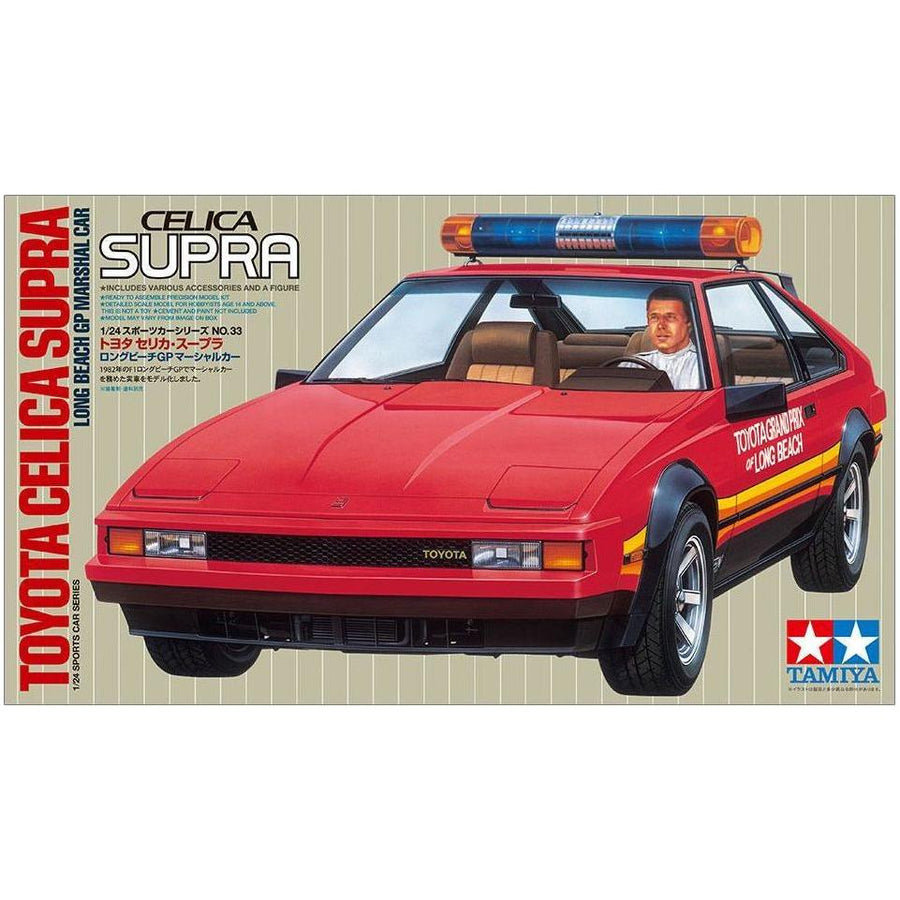

Vintage RC vehicles represent a unique era in remote control hobby history—a time when mechanical ingenuity and simple designs created surprisingly capable machines. These classics from the 80s and 90s have a charm that modern RCs often lack, with their distinctive mechanical transmissions, simpler electronics, and those iconic boxy body shapes that defined an era.

Many hobbyists don't realise just how different these classics are from their modern counterparts. While today's RC cars feature sophisticated computerised controls and composite materials, vintage models relied on mechanical differentials, simpler suspension geometry, and often employed nylon rather than engineered plastics. This isn't just nostalgia talking—there's something genuinely special about the engineering solutions of yesteryear.

Collector Value Considerations

The value of vintage RC models can vary dramatically depending on several factors:

- Rarity: Limited production runs or region-specific models often fetch premium prices

- Condition: Original boxes, manuals, and virgin parts significantly increase collectability

- Completeness: Missing pieces can dramatically reduce value, especially rare plastic parts

- Historical significance: Models that introduced groundbreaking features or won major competitions tend to be more sought after

It's worth noting that even seemingly minor details like original sticker placement can affect collector value. Most serious collectors prefer models with factory-applied decals rather than aftermarket replacements, even if the replacements are identical. This is why proper preservation using specialised tools and appropriate lubricants is so important.

Common Challenges with Vintage RCs

Let's be honest—owning a vintage RC ain't always smooth sailing. These decades-old machines come with their own unique set of challenges:

- Brittle plastics: Exposure to UV light and temperature fluctuations over time can make plastic parts crack under even minor stress

- Unavailable parts: Many manufacturers have long discontinued support for vintage models, making replacement parts scarce

- Electrical gremlins: Old solder joints, corroded contacts, and degraded wiring insulation can cause intermittent issues

- Battery compatibility: Finding power solutions that work with older designs without modification can be tricky

Ya don't need to be a rocket scientist to fix these issues, but ya do need patience and the right approach. Sometimes, the best solution is preventative maintenance rather than waiting for a catastrophic failure. Regular inspection using quality RC tools can help catch potential problems before they become serious.

Essential Cleaning & Surface Care

Proper cleaning is crucial for maintaining both the appearance and functionality of your vintage RC. Unlike modern models with their weather-resistant materials, older RCs often used plastics that are sensitive to harsh chemicals and abrasives. Let's break down the essential cleaning process:

Step-by-Step Cleaning Process

-

Dust Removal: Start with a soft brush or compressed air to remove loose debris and dust from the chassis, wheel wells, and suspension components.

-

Body Cleaning: For plastic body shells, use a mild soap solution (dishwashing liquid works well) and lukewarm water. Apply with a soft microfibre cloth and gently clean in circular motions. NEVER use alcohol-based products on vintage polycarbonate bodies as they can cause crazing and cracking.

-

Chassis Cleaning: Use precision brushes to reach tight spots. For stubborn grime, a slightly damp cloth with mild soap can help, but be cautious around electronics.

-

Drying: This is critical—always allow components to air dry completely before reassembly. Moisture trapped in joints can accelerate corrosion, especially in metal parts.

Pro Tip:

For vintage chrome or metal parts, avoid commercial metal polishes which can be too aggressive. Instead, use a small amount of baking soda paste on a soft cloth for gentle cleaning.

Safe Products for Vintage Materials

Not all cleaning products are created equal when it comes to vintage RC care. Here's what works best for different materials:

- Plastic Components: Mild soap and water or specialised plastic-safe cleaners

- Metal Parts: Non-abrasive metal cleaners or baking soda paste for light polishing

- Rubber/Tyres: Warm soapy water; avoid petroleum-based products which can degrade rubber

- Electronics: Isopropyl alcohol (90%+) on a cotton swab, but only for contacts and circuit boards—never on plastics

Products to completely avoid include acetone, strong solvents, and abrasive cleaners which can permanently damage vintage plastics and decals. When in doubt, always test any cleaning product on an inconspicuous area first.

Inspecting & Maintaining Key Components

Regular inspection is your best defence against catastrophic failures. Many vintage RC problems start small but can escalate quickly if not addressed. Here's how to keep your classic machine in prime condition:

Chassis and Suspension Care

The backbone of any RC vehicle is its chassis and suspension system. For vintage models, these components often require special attention:

-

Chassis Inspection: Look for hairline cracks, especially around screw holes and stress points. Early detection can prevent complete failures during operation.

-

Suspension Components: Check shock absorbers for oil leaks and ensure mounting points are secure. Vintage shocks often use simple O-rings which can dry out over time—consider replacing them with modern equivalents from our RC spares collection.

-

Fasteners: Vintage screws and nuts may have developed corrosion or weakened over time. If you notice rust or stripped threads, consider replacing them with stainless steel alternatives for improved durability.

Drive System Maintenance

The drivetrain is where most of the wear occurs in vintage RCs:

-

Gear Inspection: Look for broken or worn teeth on plastic gears. Even minor damage can quickly spread under load.

-

Bearing Care: Old bearings often become noisy and rough. Clean them carefully with a degreaser and relubricate with thin hobby oil or consider installing modern sealed bearings for improved performance.

-

Drive Shafts: Check for bends or excessive play in drive shafts and universal joints. These components are often under significant stress and can fail suddenly.

| Component | Common Issues | Maintenance Solution |

|---|---|---|

| Chassis | Stress cracks, stripped screw holes | Reinforce with epoxy, install threaded inserts |

| Suspension Arms | Brittleness, fractures at pivot points | Replace with NOS or modern equivalents |

| Gears | Worn teeth, cracked gear bodies | Replace with metal upgrades where available |

| Bearings | Rust, rough operation | Clean and relubricate or replace with sealed bearings |

Preventative Measures

An ounce of prevention is worth a kilogram of cure when it comes to vintage RCs. Here are some proactive steps you can take:

-

Stress Reinforcement: For plastic parts known to be failure-prone, consider applying small reinforcement patches using epoxy or fibreglass tape before they break.

-

Scheduled Maintenance: Don't wait for problems to appear—establish a regular maintenance schedule even if you're not using the RC frequently.

-

Spare Parts Stockpiling: If you find original or compatible replacement parts, consider purchasing extras for future needs. Certain components like suspension arms and body mounts are notorious for becoming unobtainable.

Lubrication & Fluids Mastery

Proper lubrication is essential for any mechanical system, but it's especially critical for vintage RCs where replacement parts may be impossible to find. Using the wrong lubricants can actually accelerate wear or damage vintage plastics through chemical interaction.

Choosing the Right Lubricants

Different components require different types of lubrication:

-

Bearings: Use light machine oil or hobby-specific oils for standard bearings. Avoid WD-40 or penetrating oils as these aren't true lubricants and can wash away existing grease.

-

Gears: For plastic-to-plastic gear interfaces, use a lightweight synthetic grease that won't attack polycarbonate or nylon. Many RC-specific options are available in our RC tools section.

-

Shock Absorbers: Vintage shocks often use thinner oils than modern equivalents. Start with 20-30wt shock oil for most applications.

-

Differentials: Older differentials often benefit from slightly thicker differential oils in the 5,000-7,000 cSt range to prevent leakage through worn seals.

Application Techniques

How you apply lubricants is just as important as which ones you choose:

-

Less is More: Overapplication attracts dirt and can cause excess drag. A small drop of oil or a thin layer of grease is all you need in most cases.

-

Precision Application: Use needle applicators or toothpicks to place lubricant exactly where needed rather than flooding components.

-

Cleaning Before Lubrication: Always ensure components are clean and dry before applying fresh lubricant. Mixing old and new lubricants can sometimes cause unexpected chemical reactions.

Common Lubrication Mistakes

Even experienced hobbyists make these common errors:

- Using petroleum-based products on rubber parts: This can cause rubber to swell or deteriorate

- Applying grease to electrical contacts: This insulates rather than conducts electricity

- Mixing incompatible lubricants: Some formulations can react negatively with each other

- Ignoring manufacturer recommendations: When available, always follow original specifications

For best results, use only hobby-grade lubricants from reputable manufacturers. Automotive or household lubricants often contain additives that can damage the plastics used in vintage RC components.

Battery & Electronics Preservation

The electrical systems in vintage RCs present unique challenges compared to modern models. Original components were designed for specific battery types and voltages that may no longer be readily available. Here's how to keep your vintage electrics running smoothly:

Vintage Battery Care

Older RC cars typically used nickel-cadmium (NiCd) or nickel-metal hydride (NiMH) battery packs. If you're still using these:

-

Proper Charging: Use a smart charger designed specifically for NiMH batteries rather than modern LiPo chargers.

-

Storage Charge: Store batteries at about 40-60% charge rather than fully charged or depleted. This significantly extends their lifespan.

-

Regular Cycling: Occasionally run your batteries through a full charge-discharge cycle to prevent memory effect in older NiCd cells.

-

Physical Inspection: Look for signs of corrosion, bulging, or leakage. Damaged cells should be replaced immediately as they can damage your vintage RC.

Electronics Maintenance

Vintage RC electronics were simpler but often less robust than modern systems:

-

Connector Maintenance: Clean power connectors regularly with electronic contact cleaner. Oxidation can cause significant power loss and erratic performance.

-

Speed Controller Care: Older mechanical speed controllers with physical contacts benefit from occasional cleaning with a contact cleaner. Electronic speed controllers should be checked for swollen capacitors or signs of overheating.

-

Receiver Protection: Vintage receivers often lack the waterproofing and vibration resistance of modern units. Consider adding foam padding and a protective covering if you're actively using your RC.

-

Wiring Inspection: Check wire insulation for cracks or brittleness. Heat shrink tubing can be used to repair minor insulation damage before it causes shorts.

Safety Warning:

Never attempt to repair swollen or leaking batteries. These should be safely disposed of according to local regulations. Replacements can be found in our battery collection.

Modern Alternatives

Sometimes, the best preservation strategy involves careful modernisation:

-

Battery Adapters: Consider 3D-printed or commercially available adapters that allow modern batteries to power vintage systems without permanent modification.

-

ESC Upgrades: Modern electronic speed controllers can sometimes be adapted to work with vintage motors, providing smoother operation and battery protection features.

-

Servo Replacements: When original servos fail, modern micro servos can often be fitted with minimal modification, providing improved performance and reliability.

Storage & Display Solutions

Proper storage is crucial for preserving your vintage RC, whether it's between running sessions or for long-term display. Environmental factors like temperature, humidity, and UV exposure can cause significant damage over time.

Ideal Environmental Conditions

Creating the right environment will dramatically extend the life of your vintage RC:

-

Temperature: Store between 15-25°C (59-77°F) to prevent plastic warping and battery degradation.

-

Humidity: Aim for 40-50% relative humidity. Too dry can make plastics brittle; too humid can promote corrosion.

-

Light Exposure: Keep away from direct sunlight and UV sources, which can fade decals and make plastics brittle.

-

Dust Control: Regular gentle dusting prevents abrasive particles from accumulating in moving parts.

Display Options and Techniques

When showcasing your vintage RC collection:

-

Support Points: Display stands that support the chassis rather than placing weight on the tyres prevent flat spots and suspension sag.

-

Protective Cases: Consider acrylic display cases to protect from dust while still allowing visibility. These needn't be expensive—many collectors use simple plastic storage boxes with clear sides.

-

Battery Removal: Always remove batteries during display to prevent potential leakage damage.

-

Rotation: If displaying multiple vehicles, rotate which ones are most visible to spread UV exposure evenly across your collection.

Long-Term Preservation Strategies

For those serious about long-term preservation:

-

Documentation: Keep a maintenance log including dates, parts replaced, and any modifications made.

-

Original Packaging: Store original boxes, instructions, and unused decal sheets in acid-free archival sleeves.

-

Spare Parts Inventory: Maintain an inventory of spare parts, especially those that are becoming difficult to source.

-

Climate Control: Consider a dehumidifier or climate-controlled display cabinet for particularly valuable collections.

| Storage Duration | Recommended Practices |

|---|---|

| Short-term (1-3 months) | Clean thoroughly, remove batteries, store in dust-free environment |

| Medium-term (3-12 months) | As above, plus lubricate moving parts, place silica gel packets nearby |

| Long-term (1+ years) | All above, plus climate control, UV protection, regular inspection |

Handling & Running Vintage RCs

If you're planning to run your vintage RC rather than just display it, there are special considerations to keep in mind. These machines weren't designed for the extreme performance of modern systems, and their ageing components may require a more gentle touch.

Best Practices for Usage

When taking your classic RC for a spin:

-

Gradual Warm-Up: Allow electronics and mechanical components to warm up gradually with slow, gentle movements before full-speed operation.

-

Terrain Selection: Choose appropriate running surfaces. Vintage RCs often have less ground clearance and suspension travel than modern equivalents.

-

Run Duration: Keep runs shorter than you might with modern RCs—10-15 minutes is plenty before allowing components to cool down.

-

Weather Considerations: Avoid running in extreme temperatures or wet conditions that can stress aged components.

Terrain Considerations

Not all surfaces are created equal when it comes to vintage RCs:

- Ideal Surfaces: Smooth, hard-packed dirt, short grass, or smooth pavement

- Problematic Surfaces: Long grass, rocky terrain, muddy areas, extremely dusty environments

- Indoor Options: Carpet tracks or smooth concrete floors provide controlled environments for running

If you're serious about running your vintage RC regularly, consider investing in a set of modern RC tyres that match the original dimensions but provide improved grip and durability.

Post-Run Maintenance

What you do after running is just as important as pre-run preparation:

-

Immediate Cleaning: Don't let dirt and debris sit on your vintage RC. Clean it thoroughly as soon as practical after use.

-

Inspection: Check for loose screws, signs of wear, or damage that may have occurred during operation.

-

Lubrication: Apply fresh lubricant to moving parts after cleaning, especially if you've been running in dusty conditions.

-

Battery Care: Remove batteries and store them properly after use. Never leave them in the model long-term.

Remember, the goal isn't just to run your vintage RC—it's to preserve it for future enjoyment. A few minutes of post-run care can add years to the life of your classic machine.

Frequently Asked Questions

How often should I lubricate my vintage RC?

For regularly used vintage RCs, apply fresh lubricant after every 3-5 running sessions. If your classic machine is primarily displayed, a light application of appropriate hobby lubricants every 3-6 months will prevent seized bearings and dried-out gear interfaces. Remember—less is more when it comes to lubrication. Excess oil and grease attract dust and can actually accelerate wear over time.

Can I use modern LiPo batteries in my vintage RC?

While technically possible, using modern LiPo batteries in vintage RCs requires careful consideration:

- Voltage must match the original specifications to prevent motor and electronics damage

- A proper LiPo cutoff system should be installed to prevent battery damage

- Physical mounting may require adaptation, as LiPos are typically lighter and differently shaped

- Original speed controllers often lack the protection circuits modern LiPos require

- Consider using NiMH batteries as a safer alternative that's closer to the original power source

What's the best way to repair cracked vintage plastic parts?

To repair cracked plastic components on vintage RCs:

- Clean both surfaces thoroughly with isopropyl alcohol

- For structural parts, use plastic-specific epoxy rather than superglue

- Reinforce the repair from behind with small strips of fibreglass or plastic

- Allow repairs to cure completely (24+ hours) before applying stress

- For high-stress areas, consider sourcing original replacement parts rather than repairing

For valuable collector items, remember that poorly executed repairs can significantly reduce value. When in doubt, consult our experienced staff at Hearns Hobbies for advice on your specific model.

Conclusion

Taking proper care of your vintage RC isn't just about maintaining a toy—it's about preserving a piece of hobby history. These classic machines represent a golden era of RC development when mechanical innovation and simple, robust designs created experiences that still bring joy decades later. With the right maintenance approach and suitable RC tools, your vintage treasure can continue performing for generations to come.

Remember that vintage RC care is as much about patience and prevention as it is about repair and restoration. Regular inspection, appropriate lubrication, and proper storage will prevent most catastrophic failures before they occur. When problems do arise, take the time to properly diagnose issues rather than applying quick fixes that might cause more damage in the long run.

Final Thoughts:

Whether you're displaying your vintage RC as a cherished collectible or still enjoy taking it for an occasional spin, proper care ensures these classic machines will be around for future enthusiasts to appreciate. The extra effort you invest today will pay dividends in both performance and preservation value for years to come. So grab your precision tools, round up some quality lubricants, and give your vintage RC the attention it truly deserves!

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments