Scale Model Kit Bash Disasters and How to Salvage Them

We've all been there. That ambitious kitbash project that started with such promise now sits on your workbench looking like a plastic crime scene. Maybe you tried combining a Tamiya tank hull with an Italeri turret, or perhaps you attempted to graft aircraft parts onto a ship model. Whatever went wrong, that sinking feeling in your stomach is all too familiar.

At Hearns Hobbies, we see the aftermath of kitbashing attempts gone sideways more often than you'd think. The good news? Most disasters aren't actually disasters – they're learning opportunities disguised as melted plastic and wonky proportions. With the right techniques and a healthy dose of patience, even the most catastrophic kitbash can be transformed into something presentable, or at least salvaged for parts.

Kitbashing represents one of the most creative aspects of scale modelling, where imagination meets engineering. It's where modellers push boundaries, creating unique vehicles and scenes that never existed in reality. But when you're cutting up perfectly good kits and forcing parts together that were never meant to meet, things can go pear-shaped faster than you can say "cyanoacrylate."

This guide isn't about perfect kitbashing techniques – there are plenty of those already. Instead, we're diving into the messy reality of when projects go wrong. We'll explore common disasters, recovery methods, and most importantly, how to learn from these experiences so your next kitbash doesn't end up in the bin. Because let's face it, every experienced modeller has a box of "learning experiences" hidden somewhere in their workshop.

Table of Contents

Common Kitbashing Disasters

Understanding the most frequent kitbashing catastrophes helps you recognise when things are starting to go sideways. Sometimes the difference between a minor hiccup and a complete disaster is catching the problem early. Let's explore the hall of shame that every kitbasher eventually encounters.

Scale mismatches top the list of kitbashing disasters. You'd think checking the scale would be obvious, but in the excitement of a creative idea, it's surprisingly easy to grab that 1:48 aircraft cockpit for your 1:35 tank conversion. The problem often isn't apparent until you're halfway through cutting and realise your tank commander would need to be eight feet tall to fit. Even within the same scale, proportions between manufacturers can vary wildly – Dragon kits and Tamiya kits might both be 1:35, but their interpretation of measurements can differ significantly.

Plastic incompatibility creates another category of disasters. Not all plastics play nicely together, and discovering this after applying solvent cement is heartbreaking. Some plastics melt at different rates, others don't bond at all, and mixing ABS with polystyrene can create weak joints that fail weeks later. The worst cases involve plastics that chemically react, creating a gooey mess that resembles melted cheese more than a scale model. Add resin parts to the mix, and you've got a whole new level of potential incompatibility issues.

Structural failures often emerge when ambition exceeds engineering. That massive turret from a modern tank might look awesome on a World War II chassis, but the weight distribution turns your model into a see-saw. Or perhaps you've created a vehicle so top-heavy it won't stay upright without a hidden support stand. Sometimes the disaster isn't immediate – everything looks fine until you pick up the model and hear that sickening crack as overstressed joints give way.

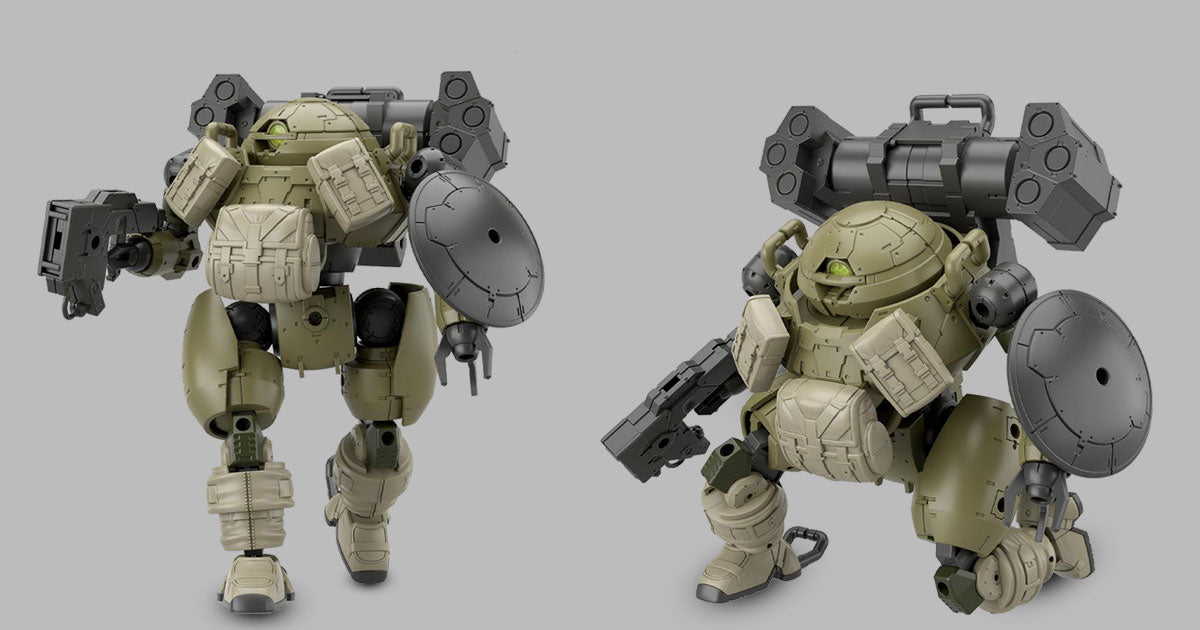

![[SUGGESTED IMAGE: Before and after comparison of a kitbash disaster showing mismatched scales and structural issues]](https://www.hearnshobbies.com/cdn/shop/files/96b881d1cfddde32db3890eb6f795e09.jpg?v=1734700590&width=700)

Disaster Assessment and Triage

Before reaching for the bin, take a deep breath and assess the damage objectively. Many kitbash disasters look worse than they actually are, especially when you're frustrated and covered in plastic shavings. A systematic evaluation helps determine whether you're dealing with a minor setback or a genuine write-off.

Start with structural integrity. Gently test all joints and connections – better to find weak points now than after you've spent hours on finishing work. Check for stress fractures, especially around areas where you've removed material or added weight. Use a magnifying glass to inspect joints; hairline cracks often preview future failures. If the basic structure is sound, you're already ahead of the game. Even models with significant cosmetic damage can be saved if the bones are good.

Surface damage assessment requires brutal honesty. Those gouges from overzealous cutting might be fillable, but melted areas from too much cement present bigger challenges. Run your finger over damaged areas – if you can feel the problem, viewers will see it. However, remember that modern fillers and sanding tools can work miracles. Document the damage with photos; it helps track your repair progress and provides reference for similar future projects.

Consider the time investment versus starting fresh. Sometimes the learning experience justifies pushing through, other times a clean slate makes more sense. Factor in the rarity and cost of the kits involved – butchering a limited edition kit hurts more than experimenting with readily available models. Also consider your skill level; what seems impossible now might be manageable after gaining experience on less critical projects.

Emotional assessment matters too. If looking at the project fills you with dread, taking a break might be wise. Many successful kitbashes were disasters that sat in a box for months before the modeller found fresh inspiration. There's no shame in shelving a project temporarily – sometimes distance provides the perspective needed to see creative solutions.

Triage Checklist

Before declaring a kitbash unsalvageable, check: Is the basic structure intact? Can visible damage be filled or hidden? Are the parts still available if you need replacements? Would the repair teach valuable skills? Sometimes the worst disasters become the best learning experiences.

Structural Repair Techniques

When your kitbash literally falls apart in your hands, structural repairs become priority one. These fixes might not be pretty initially, but they provide the foundation for all subsequent recovery work. Think of this phase as surgery – it's messy, but necessary for the patient's survival.

Reinforcement strategies vary based on the failure type. For joints that won't hold, drilling and pinning provides mechanical strength that adhesives alone can't match. Pin vices and drill bits in various sizes let you add brass or steel rod reinforcements invisibly. The key is drilling straight and centered – a wonky pin creates more problems than it solves. For larger structural members, consider laminating plastic sheet inside hollow areas for invisible strength.

Reconstructing missing or destroyed sections requires creativity and patience. Start by creating a framework using plastic rod or sheet, building up the basic shape before worrying about details. Donor kits provide excellent sources for replacement parts – that ruined turret might be replaced by one from a different kit with minor modifications. Sometimes the replacement part comes from an unexpected source; model railway buildings often provide useful architectural details for military models.

Gap-filling represents a critical skill in disaster recovery. Small gaps respond well to standard putty, but larger voids need different approaches. Built-up layers of CA glue and baking soda create rock-hard fills for structural gaps. For curved surfaces, two-part epoxy putty allows sculpting replacement sections that can be carved and sanded once cured. The trick is working in stages – trying to fill massive gaps in one go usually results in sagging or cracking.

Weight distribution fixes often save top-heavy kitbashes. Adding weight to the base using fishing sinkers or lead shot shifts the center of gravity lower. For vehicles, hiding weights inside hull spaces or under chassis components maintains appearance while improving stability. In extreme cases, creating a new base with a wider footprint provides stability without modifying the model itself. Remember that display bases can discretely incorporate support structures.

![[SUGGESTED IMAGE: Step-by-step structural repair showing pinning technique and gap filling process]](https://www.hearnshobbies.com/cdn/shop/files/G5068578.jpg?v=1750896152&width=1200)

Surface Recovery Methods

Once the structure is solid, attention turns to surface restoration. This phase transforms your Frankenstein's monster back into something resembling a scale model. Surface work requires patience and progressively finer techniques, but the results justify the effort.

Filling and smoothing techniques depend on the damage extent. Small scratches and gaps respond well to standard modelling putty applied with a spatula and smoothed with a wet finger. Larger areas benefit from two-part putties that can be sculpted before curing. The secret lies in slightly overfilling, then sanding back to the correct contour. Multiple thin applications work better than one thick layer, preventing shrinkage and cracking.

Rescribing lost detail becomes necessary after filling work obliterates panel lines and surface features. Using scribing tools and templates, you can restore panel lines that match the surrounding detail. Photos of the original kit help maintain accuracy. Sometimes it's better to remove all detail from a panel and rescribe from scratch rather than trying to match existing lines. This approach often produces cleaner results than piecemeal repairs.

Texture matching presents unique challenges, especially when different kit manufacturers use varying surface textures. Cast texture can be replicated using liquid cement stippling, while fine sanding tools help match smooth surfaces. For zimmerit or anti-slip textures, two-part putty can be textured before curing using appropriate tools. Sometimes adding texture to entire sections provides better results than trying to match existing texture perfectly.

Surface preparation for painting requires extra attention on repaired models. Primer becomes your best friend, revealing flaws that need additional work before committing to paint. Quality primers also help unify different plastic types and colours, providing consistent paint adhesion. Don't rush this stage – finding problems after base coating means starting the surface work again.

Surface Recovery Quick Reference

| Damage Type | Recommended Fix | Tools Needed |

|---|---|---|

| Small gaps/scratches | Standard putty | Spatula, sandpaper |

| Large voids | Epoxy putty/plastic sheet | Sculpting tools, files |

| Lost detail | Rescribing | Scribing tools, templates |

| Texture mismatch | Retexturing entire panel | Putty, texture tools |

Creative Cover-Up Solutions

Sometimes the best fix isn't a repair – it's a creative reimagining that turns your disaster into a feature. This approach requires shifting perspective from "fixing what went wrong" to "creating something intentionally different." Many award-winning models started as kitbashing disasters that forced creative solutions.

Battle damage provides the ultimate cover-up for structural failures and surface problems. That weak joint becomes a shell hit, the melted plastic transforms into heat damage, and misaligned parts suggest field repairs. Weathering products help sell the effect, while pigments add realistic rust and dirt accumulation around damaged areas. The key is consistency – if you're showing battle damage, it needs to tell a coherent story across the entire model.

Environmental storytelling turns mistakes into narrative elements. That poorly fitting turret? It's a field modification using salvaged parts. Mismatched colours suggest replacement panels from different vehicles. Adding stowage and equipment helps sell the story while hiding problem areas. Tarps and camo netting conveniently cover troublesome joints while adding visual interest. Sometimes a few crew figures performing maintenance explains why panels don't quite fit properly.

Conversion camouflage involves adding elements that distract from or incorporate the problematic areas. External armor plates, sandbags, or spare track links can hide a multitude of sins while looking purposeful. Photo-etch details draw the eye away from rough areas while adding sophistication. The goal isn't deception – it's integration of the flaws into an overall design that looks intentional.

Post-apocalyptic or sci-fi conversions offer ultimate creative freedom. Those mismatched parts and rough joints? Perfect for a vehicle cobbled together after civilisation's collapse. Scale inconsistencies make sense when you're building something that never existed. Adding chains, spikes, and improvised armor transforms a failed historical model into a unique creation. This approach works particularly well for competition categories that reward creativity over accuracy.

Creative Mindset

When facing a kitbash disaster, ask yourself: "What would this look like in a different context?" A failed modern tank might become an excellent post-apocalyptic survivor. A botched aircraft could transform into a crashed wreck diorama. Sometimes the best models come from embracing the unexpected.

Parts Salvage Operations

When a kitbash proves truly unsalvageable, professional salvage operations ensure nothing goes to waste. That disaster sitting in your shame box contains valuable parts for future projects. Learning to see failed models as parts resources transforms disappointments into opportunities.

Disassembly techniques vary based on how the model was constructed. Cement welded parts require careful cutting with razor saws to separate components without damage. CA glued assemblies sometimes release when frozen – the differential contraction can break bonds. For painted models, paint strippers restore parts to useable condition. Document what you salvage; future you will appreciate knowing what's in that parts box.

Parts organisation prevents salvaged components from becoming another mess. Small storage containers labeled by type (wheels, weapons, detail parts) make finding specific items easy. Photograph unusual parts before storage – visual references help when you can't remember what that strange component originally was. Consider keeping instruction sheets from sacrificed kits; they provide parts identification and assembly references.

Selective salvage focuses on high-value components. Expensive photo-etch sets, turned metal barrels, and resin accessories deserve careful recovery. Even from plastic kits, certain parts prove invaluable – clear parts, unique weapons, or detailed engines often cost more separately than entire kits. Wheels and tracks from armor kits provide excellent detailing for other projects.

Learning from salvage helps prevent future disasters. As you disassemble failed kitbashes, analyse what went wrong. Was it poor planning, incompatible materials, or overambitious engineering? Each salvage operation provides insights that improve future projects. Keep notes about what worked and what didn't – these lessons prove more valuable than the salvaged parts themselves.

![[SUGGESTED IMAGE: Organized parts storage system showing salvaged components sorted in labeled containers]](https://www.hearnshobbies.com/cdn/shop/files/G5068375-1.jpg?v=1749780090&width=700)

Prevention Strategies

While salvaging disasters builds character, preventing them saves time, money, and frustration. Smart planning and methodical approaches reduce kitbashing risks without limiting creativity. These strategies come from the school of hard knocks – lessons learned from countless modellers' mistakes.

Dry fitting obsessively prevents most structural disasters. Before cutting anything, test fit all major components multiple times. Use poster putty or tape to temporarily hold parts while checking proportions and clearances. Take photos from multiple angles – sometimes problems obvious in pictures get missed in person. When combining kits from different manufacturers, expect fit issues and plan accordingly. That extra hour spent dry fitting saves days of repair work.

Material testing eliminates chemistry disasters. Before committing to a full build, test your adhesives and paints on hidden areas or spare parts. Not all plastics react identically to solvents, and some combinations create unexpected results. Different cements work better with specific plastics – knowing which to use when prevents melting mishaps. Create a test piece using scraps from all kits involved to verify compatibility.

Documentation throughout the process provides insurance against memory failures. Photograph each stage, especially before making irreversible cuts. Keep notes about what parts came from which kits – six months later, you won't remember that the turret ring came from kit A while the hull modification followed kit B's instructions. These records also help when ordering replacement parts or planning similar projects.

Incremental building reduces cascade failures. Instead of assembling everything then discovering problems, work in stages with testing between each phase. Build the basic structure, verify it's solid, then add the next level of detail. This approach catches issues early when they're easier to fix. It also provides natural stopping points if you need breaks – kitbashing marathons often lead to tired mistakes.

Planning Phase

- • Research scale compatibility

- • Check plastic types

- • Gather reference images

- • Test fit everything

- • Plan cut sequences

Execution Phase

- • Work in stages

- • Test adhesives first

- • Document progress

- • Keep spare parts handy

- • Take regular breaks

Disaster to Success Stories

Every experienced modeller has stories of disasters transformed into triumphs. These tales provide inspiration when you're staring at your own plastic catastrophe, wondering if the bin might be the best option. Success often comes from persistence and creative problem-solving rather than perfect execution.

Consider the classic "melted tank syndrome" recovery. One modeller accidentally used hot cement on a Tamiya Sherman, creating a Salvador Dali-esque mess. Instead of binning it, they transformed it into a knocked-out tank with fire damage. Strategic application of weathering products and soot pigments turned the melted areas into realistic heat damage. The finished diorama won a gold medal at a local competition.

Scale mismatch disasters often become unique conversation pieces. A modeller combining a 1:35 tank hull with a 1:48 aircraft turret initially despaired at the proportions. By reimagining it as a captured vehicle modified by desperate defenders, the odd proportions became part of the story. Adding improvised armor from truck kit parts and battle damage sold the narrative. Sometimes embracing the mistake creates more interesting models than the original plan.

Structural failures can inspire innovative solutions. When a ambitious kitbasher's flying tank conversion proved too heavy for its wings, they created a crash landing diorama instead. The broken wings became impact damage, and the addition of fleeing crew figures and scattered equipment told a dramatic story. What started as an engineering failure became a dynamic scene that showcased advanced weathering and storytelling skills.

The lesson from these recoveries remains consistent: flexibility and creativity transform disasters into opportunities. That failed kitbash teaches more about modelling than a dozen perfect builds. Each mistake builds problem-solving skills that elevate your entire modelling practice. Plus, you'll have great stories to share at the hobby shop when another modeller shows up with their own disaster seeking advice.

Frequently Asked Questions

What's the most important tool for salvaging kitbash disasters?

While quality tools help, patience proves most valuable. After that, a good pin vise for reinforcement, quality putty for filling, and sharp blades for clean cuts form the essential toolkit. Many modellers swear by two-part epoxy putty for major reconstructions. But honestly? The most important tool is the ability to step back, assess calmly, and approach fixes methodically rather than frantically trying to save a disaster in one session.

When should I give up on a kitbash and start over?

If the basic structure can't support its own weight or the main components are irreparably damaged, starting fresh might be wise. Also consider the time investment – if repairs will take longer than building from scratch, that's a sign. However, rare or expensive kits deserve heroic salvage efforts. When you dread working on it or it's been sitting untouched for over a year, either commit to a creative reimagining or salvage the parts for future projects.

Can I mix plastic types in kitbashing, and how do I make them work together?

Yes, but carefully. Test adhesives on scrap pieces first – CA glue works across most plastic types while plastic cement only bonds styrene. Mechanical connections using pins or screws provide insurance for dissimilar materials. Epoxy adhesives create strong bonds between different plastics. Prime everything thoroughly before painting to ensure uniform finish across different materials.

What's the best way to hide major gaps in kitbashed models?

Layer your approach: fill deep gaps with plastic strip or rod first, then use putty for fine work. For curved areas, two-part putty allows sculpting to match contours. Sometimes adding a detail like a weld bead or armor plate makes more sense than trying to achieve invisible repairs. Strategic placement of stowage, equipment, or weathering can disguise problems while adding visual interest. Remember, the goal is a convincing model, not necessarily perfect joint lines.

Final Thoughts

Kitbashing disasters happen to everyone, from beginners to master modellers. The difference lies not in avoiding mistakes but in how we respond to them. Every melted joint, mismatched scale, and structural failure teaches lessons that instruction sheets can't provide. These hard-won skills separate competent modellers from truly creative ones.

At Hearns Hobbies, we've seen countless "failures" transformed into competition winners through persistence and imagination. That disaster on your bench might be frustrating now, but it's also an opportunity to develop problem-solving skills that'll serve you throughout your modelling journey. Whether you salvage it, transform it, or strip it for parts, you'll emerge a better modeller.

Remember, some of the hobby's most innovative techniques came from creative solutions to disasters. Today's mistake might inspire tomorrow's masterpiece. So before you bin that kitbash catastrophe, take a breath, grab your tools, and see what lessons it has to teach. Your future projects will thank you for the experience gained wrestling with current challenges.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments