Do You Need a Powerbase Kit? Here's When It's Worth It

Discover when magnetic traction assistance becomes essential for your model railway

Power interruptions and voltage inconsistencies can derail even the most carefully planned model railway setups. Have you ever watched a prized OO gauge locomotive stutter mid-climb, or seen your digital control system lose sync during what should've been a smooth session? If so, you'll understand the frustration that comes with unreliable traction. We're going to cut through the marketing speak and explain when a Powerbase Kit is actually worth your investment. Whether you're just getting started with a starter train set or you're fine-tuning a complex DCC-controlled layout, understanding the benefits of electromagnetic assistance could turn out to be the smartest upgrade you make for your railway.

So if you've invested in quality models from Hornby or PECO, and you're wondering why your trains still falter on inclines or struggle through tight curves - this guide might just be the solution your setup's been missing.

| Powerbase Kit Guide at a Glance | |

|---|---|

| What It Is | Magnetic traction-boosting system using track-mounted magnets and locomotive plates |

| Best For | Steep gradients, heavy consists, small-scale locos, and complex track layouts |

| Installation | Non-destructive retrofit or during initial construction, compatible with DCC systems |

| Skip It If | Flat layouts, short consists, display-only setups, or pristine track conditions |

What Is a Powerbase Kit?

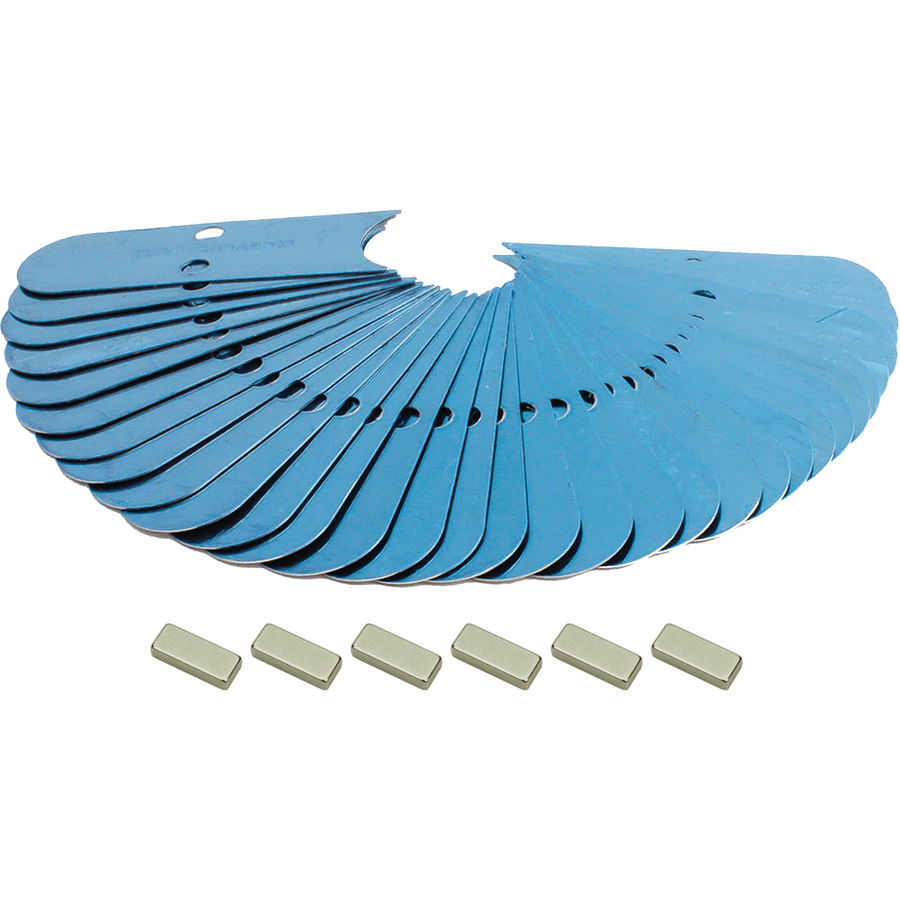

A Powerbase Kit is essentially a traction-boosting upgrade that's designed to improve how your model trains perform, particularly on layouts with inclines or those tricky tight curves that seem to catch every locomotive off-guard. The system works by using magnets that you install beneath the track and ferrous strips or plates that get mounted on the underside of your locomotives or rolling stock. What you get is increased wheel-to-rail adhesion without messing up the visual aesthetics of your carefully planned setup.

The magnetic force creates what's essentially a downward pull that mimics real-world physics - think of how actual trains benefit from their sheer weight pressing down on the rails. But unlike adding physical weight to your models (which can stress motors and cause other problems), magnetic assistance provides consistent downforce that varies with the strength of the magnets you choose.

Brands like DCC Concepts offer Powerbase Kits that are specifically engineered for easy integration with modern layouts, especially those running DCC control systems. These aren't aftermarket bodge jobs - they're purpose-built solutions that work alongside your existing track systems without requiring major modifications.

The beauty of a well-designed Powerbase Kit lies in its invisibility once installed. Your visitors won't see bulky add-ons or obvious modifications, just trains that seem to grip the rails with supernatural confidence. The magnetic plates sit flush under your locomotive chassis, while the track magnets are completely hidden beneath your scenic work.

What sets quality Powerbase Kits apart from cheaper alternatives is the engineering precision. The magnetic strength is calibrated to provide assistance without creating unwanted drag or interfering with your digital decoders. You're not fighting against magnetic forces when your trains need to coast or brake - the system enhances performance without compromising control.

When Do You Need One?

Not every model railway setup will benefit from a Powerbase Kit, but if you're experiencing any of these issues, it's definitely worth considering. Your layout includes gradients steeper than 2% - this is where physics starts working against even well-maintained locomotives, and where magnetic assistance really proves its worth.

You're regularly hauling long consists of HO rolling stock or heavy freight wagons, particularly those loaded shipping containers that look fantastic but add significant weight to your trains. The more carriages you're pulling, the more likely you are to experience wheel slippage during acceleration or when navigating inclines.

Wheel slippage during acceleration or on bends is a telltale sign that your locomotives are struggling for grip. This is especially common with N gauge locomotives or small wheelbase models that simply don't have the physical mass to maintain consistent rail contact. The smaller the scale, the more pronounced these traction issues become.

Many modellers underestimate how much weight distribution and gradient physics affect their layouts. Real trains benefit from enormous weight pressing their wheels down onto the rails, but our scale models often lack sufficient downforce to maintain reliable contact. A Powerbase Kit applies constant, controllable downforce that mimics real-world adhesion without compromising the delicate suspension systems or damaging your carefully laid railway track.

If your steam locomotives are slipping on grades that real steam engines would handle easily, magnetic assistance can restore realistic performance to your operations.

The physics are straightforward - insufficient adhesion leads to wheel spin, which wastes power and creates inconsistent performance. Your locomotive motors work harder when wheels slip, generating heat and reducing their lifespan. Magnetic assistance ensures that the power your motor produces actually translates into forward motion rather than just spinning wheels.

Who Benefits the Most?

Different types of modellers will find varying levels of benefit from Powerbase Kits, and understanding where you fit can help determine whether the investment makes sense for your specific situation.

| Modeller Type | Primary Benefits | Recommended Focus |

|---|---|---|

| Beginners with Starter Sets | Dramatically improves performance on uneven home layouts or temporary carpet setups where track isn't perfectly level | Train Sets with basic analogue controllers |

| Advanced DCC Users | Pairs exceptionally well with programmable acceleration and braking curves, allowing more realistic operation | Digital Systems and sound decoders |

| Freight Modellers | Prevents slippage with heavy consists and enables realistic slow-speed shunting operations | Diesel Locomotives and goods wagons |

| Small Scale Enthusiasts | Overcomes the inherent traction limitations of lightweight N and Z scale models | N Scale sets and compact layouts |

Beginner modellers often struggle with traction issues because they're setting up layouts on less-than-ideal surfaces. A dining room table that's not perfectly level, or track laid directly on carpet, creates conditions where even minor undulations can cause problems. Powerbase Kits can compensate for these imperfections, making your first train set perform far better than you might expect.

Advanced DCC users appreciate how magnetic assistance integrates with sophisticated control systems. When you're programming realistic acceleration curves and momentum settings through your DCC decoder, having reliable traction means these advanced features actually work as intended. Your locomotives can start smoothly under load and maintain consistent speeds on grades.

Freight operations particularly benefit because heavy consists are exactly where traction problems become most apparent. If you're modelling Australian freight operations with multiple Australian locomotives hauling long rakes of loaded wagons, magnetic assistance can make the difference between realistic operation and constant frustration.

Installation & Optimisation

Installing a Powerbase Kit is more straightforward than many modellers expect, though it does require some planning and attention to detail. Most quality kits include everything you need: magnet plates for your track sub-roadbed, steel or magnetic strips for locomotive undersides, plus templates and spacing guides to ensure proper alignment.

The key to successful installation is ensuring your track base is level and solid before you begin embedding the magnets. Any flexibility or unevenness in your baseboard will affect how consistently the magnetic force is applied. If you're building a new layout, this is definitely the time to install your Powerbase Kit - retrofitting is possible but significantly more complex.

For track-mounted magnets, you'll typically route shallow channels in your baseboard to accommodate the magnetic strips. The depth needs to be precise - too shallow and the magnets will interfere with your track pins, too deep and the magnetic field won't be strong enough to affect your locomotives effectively. Most manufacturers provide detailed templates, but it's worth double-checking measurements before you start cutting.

Locomotive modification is usually the simpler part of the process. The ferrous plates or magnetic strips attach to the underside of your locomotive chassis using either strong adhesive or small screws, depending on the kit design. The trick is positioning them so they align with your track magnets while avoiding interference with locomotive wheels or drive mechanisms.

Digital control users will want to combine their Powerbase Kit with quality point motors for seamless integration. Systems like Cobalt iP Digital motors work particularly well because they provide the precise control needed to take full advantage of improved traction characteristics.

Installation Tip:

Test your magnetic field strength with temporary positioning before committing to permanent installation. Too much magnetic force can actually hinder smooth operation, while too little won't provide meaningful benefit.

The spacing between track magnets matters more than you might think. Place them too close together and you create zones of uneven magnetic force that can cause jerky movement. Space them too far apart and your locomotives will experience inconsistent traction assistance. Most successful installations use magnets spaced at intervals that match the wheelbase of your primary locomotives.

Common Mistakes

Even experienced modellers can run into trouble when installing Powerbase Kits, usually because they underestimate how precise the installation needs to be. One of the most frequent errors is assuming that "more magnetic force equals better performance" - this simply isn't true, and excessive magnetic pull can actually make your trains harder to control rather than easier.

Magnet alignment issues cause more problems than any other installation mistake. If your track magnets aren't perfectly aligned with the locomotive plates, you'll get uneven pulling forces that can cause your trains to derail or bind up in curves. Take time to mark your magnet positions carefully and test with actual locomotives before making anything permanent.

Many modellers make the mistake of installing Powerbase systems without considering their track cleaning routine. Magnetic systems can attract metal particles and debris, which then interfere with both electrical contact and smooth operation. You'll need to modify your maintenance schedule to account for this, possibly investing in specialised track cleaning equipment designed for magnetically-assisted layouts.

Interference with electronics is another common issue, particularly with sound decoders and sensitive digital systems. Some magnetic configurations can create electromagnetic fields that interfere with decoder operation or cause strange behaviour in DCC systems. Always test your digital equipment thoroughly after installation.

Trying to retrofit Powerbase systems to existing layouts often leads to compromises that reduce effectiveness. If your track is already scenicked and ballasted, accessing the areas where magnets need to be installed becomes challenging. Some modellers attempt workarounds that result in suboptimal magnetic field placement, which defeats the purpose of the system.

Alternatives to Consider

Before committing to a Powerbase Kit, it's worth exploring other traction improvement options that might be more suitable for your specific situation. Traction tyres are a traditional solution that many European locomotives use effectively. These rubber rings fit around locomotive driving wheels and provide excellent grip, though they do require periodic replacement and can affect the visual authenticity of your models.

Weighted locomotives are another approach - adding small amounts of lead or steel shot to increase downforce naturally. This works well for large scale locomotives that have space for additional weight, though it's less practical for smaller scales where every gram affects performance.

High-quality replacement wheelsets can significantly improve traction by ensuring better electrical contact and more consistent rail interface. Many factory-fitted wheels aren't perfectly round or true, and upgrading to precision locomotive wheels can resolve traction issues without additional complexity.

| Solution | Best For | Limitations |

|---|---|---|

| Powerbase Kit | Permanent layouts with grades | Installation complexity, ongoing maintenance |

| Traction Tyres | Individual locomotive upgrades | Periodic replacement, visual impact |

| Added Weight | Large scale models with space | Motor strain, not suitable for small scales |

| Precision Wheelsets | Improving existing locomotives | Limited improvement on severe grades |

Track maintenance improvements often provide better value than traction assistance systems. Investing in quality rail cleaning equipment and establishing a regular maintenance routine can eliminate many apparent traction problems. Sometimes what seems like a grip issue is actually poor electrical contact due to dirty rails or oxidised rail joiners.

Cost vs. Benefit Analysis

Understanding the real-world costs of Powerbase Kits helps determine whether they represent good value for your specific situation. A quality kit suitable for a modest layout typically costs between $150-300 AUD, depending on the coverage area and manufacturer. This needs to be weighed against the improvements you'll actually experience and the complexity of installation.

Installation costs can add significantly to the total investment if you're not comfortable doing the work yourself. Professional installation might add another $200-400 to your total cost, depending on your layout's complexity and local labour rates. Factor in potential track reconstruction if you're retrofitting an existing layout.

The time investment is substantial - expect to spend several weekends on installation and testing, even with a straightforward setup. For many modellers, this time could be spent on other improvements that might provide more visible benefits, such as enhanced scenery materials or upgraded lighting systems.

Consider the ongoing maintenance requirements. Magnetic systems attract metal debris more readily than standard track, potentially requiring more frequent track cleaning sessions. The magnetic plates on locomotives also need periodic inspection to ensure they haven't shifted or become damaged.

However, for layouts where traction issues are genuinely limiting operations, the benefits can be transformative. Being able to reliably haul realistic consists up realistic grades, or operate heavy freight trains at prototypically slow speeds, might justify the investment for serious modellers focused on operational realism.

Calculate the cost per locomotive that will benefit from magnetic assistance - if you're only improving traction for one or two engines, individual solutions like traction tyres might be more economical.

The resale value consideration is mixed. While Powerbase systems can make a layout more attractive to buyers who understand their benefits, they also represent a specialised modification that might not appeal to all potential purchasers. Some buyers might actually see them as complications rather than improvements.

Frequently Asked Questions

Can I install a Powerbase Kit on existing track?

Yes, but retrofitting is significantly more complex than installation during initial construction. You'll need to carefully remove sections of ballast and scenery to access the track base for magnet installation. Consider whether the disruption to your existing layout justifies the benefits, especially if your current setup is already scenicked.

Will magnetic assistance interfere with my DCC system?

Quality Powerbase Kits are specifically engineered to avoid interference with DCC control systems and sound decoders. However, always test your digital equipment thoroughly after installation, as some configurations can create electromagnetic fields that affect sensitive electronics.

How often do Powerbase systems need maintenance?

Magnetic systems attract metal debris more readily than standard track, requiring more frequent track cleaning sessions. The locomotive-mounted magnetic plates should be inspected periodically to ensure they haven't shifted or become damaged. Plan for slightly increased maintenance compared to conventional setups.

Are Powerbase Kits worth it for flat layouts?

Generally no - if your layout is predominantly flat with minimal gradients and you're running short consists, the investment probably isn't justified. Powerbase systems excel on layouts with steep inclines, heavy freight operations, or where traction issues genuinely limit realistic operations.

Can I use traction tyres and magnetic assistance together?

Yes, combining traction tyres with magnetic assistance can provide exceptional grip, though it's usually overkill for most applications. This combination works particularly well for heavy freight operations or extreme gradients where maximum traction is essential.

Conclusion

Powerbase Kits represent a sophisticated solution to traction problems that can genuinely transform layouts where grip issues limit realistic operations. Whether you're struggling with heavy freight consists on steep gradients or trying to achieve prototypically slow shunting speeds, magnetic assistance can provide the consistent traction that makes these operations possible.

The key to success lies in honest assessment of your needs. If your layout features significant gradients, heavy freight operations, or small-scale locomotives that struggle for grip, a Powerbase Kit could be the upgrade that finally allows your railway to operate as intended. The investment is substantial, both in terms of cost and installation complexity, but for the right applications, the benefits are transformative.

However, if your layout is predominantly flat, your consists are light, or your current operations run smoothly, the complexity and cost probably aren't justified. Consider simpler alternatives like precision wheelsets or improved track maintenance before committing to magnetic assistance.

Making Your Decision:

The best Powerbase Kit installations happen when modellers have a clear understanding of their traction challenges and realistic expectations about what magnetic assistance can achieve. If you're experiencing genuine operational limitations due to poor adhesion, and you're committed to the installation process, a quality Powerbase Kit can deliver the reliable performance that transforms frustrating layouts into smoothly operating railways.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments