Essential Guide to Model Railway Maintenance

Keep your miniature world running smoothly

Model railway maintenance is the cornerstone of a well-functioning and long-lasting layout. Whether you're a novice enthusiast or a seasoned hobbyist, understanding the essentials of upkeep can significantly enhance your model railway experience. This comprehensive guide will walk you through everything from basic cleaning techniques to advanced maintenance procedures, ensuring your trains keep rolling for years to come. At Hearns Hobbies, we're committed to helping you maintain your miniature world with our extensive range of maintenance products and expert advice.

| Model Railway Maintenance at a Glance | |

|---|---|

| Key Areas | Track cleaning, wheel maintenance, lubrication, electrical connections |

| Frequency | Regular (weekly to monthly) for basic tasks, seasonal for deep cleaning |

| Essential Tools | Track cleaning rubber, lubricants, multimeter, small screwdrivers |

| Benefits | Improved performance, longevity of equipment, enhanced enjoyment |

The Importance of Regular Maintenance

Regular maintenance is crucial for preserving the functionality and appearance of your model railway. A well-maintained layout not only performs better but also retains its value over time. Consistent upkeep prevents minor issues from escalating into major problems, saving you time and money in the long run. By implementing a routine maintenance schedule, you ensure that your trains run smoothly, your tracks remain clean, and your electrical systems function optimally.

Pro Tip: Maintenance Schedule

Create a maintenance log to track your cleaning and upkeep activities. This will help you stay organized and ensure no aspect of your layout is neglected. A simple spreadsheet or notebook can suffice, noting dates of cleaning, lubrication, and any repairs made.

Essential Cleaning Techniques

Cleaning is the foundation of model railway maintenance. Regular cleaning prevents the buildup of dust, debris, and oxidation that can interfere with electrical conductivity and smooth operation. Here's how to keep your layout spotless:

Track Cleaning

Clean tracks are essential for reliable electrical contact and smooth train operation. Use these methods to maintain your tracks:

- Use a track cleaning rubber or pad to gently scrub the rails, removing dirt and oxidation.

- Apply a small amount of isopropyl alcohol on a lint-free cloth to wipe down the tracks, dissolving stubborn grime.

- For extensive layouts, consider investing in a track cleaning car that can be run around the layout, saving time and effort.

Wheel Cleaning

Clean wheels ensure good electrical contact and prevent dirt transfer to your tracks. Follow these steps:

- Use a soft cloth or specialized wheel cleaning brush to remove debris from locomotive and rolling stock wheels.

- For stubborn dirt, use a cotton swab dipped in isopropyl alcohol to clean between the wheel flanges.

- Consider using a cleaning fluid specifically designed for model train wheels, available in our maintenance tools collection.

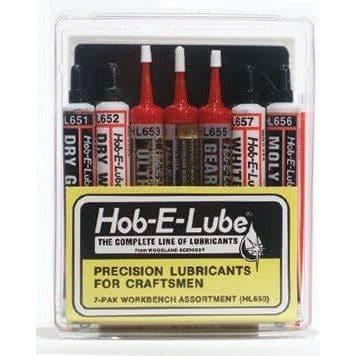

Lubrication: The Key to Smooth Operation

Proper lubrication is essential for reducing wear and ensuring smooth operation of your model trains. However, it's crucial to use the right type of lubricant and apply it sparingly to avoid attracting dust and causing more problems. Here's a guide to effective lubrication:

What to Lubricate

Focus on these key components when lubricating your model trains:

- Axles and bearings

- Gears and motor bearings

- Couplings and linkages

- Pantographs on electric locomotive models

How to Lubricate

Follow these steps for proper lubrication:

- Clean the area to be lubricated thoroughly before applying any oil.

- Use specialized model train oils designed for miniature mechanics.

- Apply lubricant sparingly using a fine-tipped applicator or toothpick.

- Wipe away any excess oil with a clean, lint-free cloth to prevent dust accumulation.

Caution: Over-Lubrication

Over-lubrication can be as problematic as under-lubrication. Excess oil attracts dust and can seep into electrical components, causing short circuits. Always err on the side of caution and apply lubricants sparingly.

Advanced Maintenance Procedures

As you become more familiar with your model railway, you may want to tackle more advanced maintenance tasks. These procedures can help you diagnose and solve complex issues, ensuring peak performance of your layout.

Electrical System Maintenance

A well-maintained electrical system is crucial for reliable operation. Regular checks and maintenance can prevent many common issues:

- Use a multimeter to check track voltage at various points around your layout, identifying any dead spots or areas of poor conductivity.

- Inspect and clean all electrical connections, including those between track sections and to your power supply.

- Check and replace any worn or damaged wires, ensuring all connections are secure.

Track Alignment and Repair

Proper track alignment prevents derailments and ensures smooth operation. Here's how to maintain your tracks:

- Regularly inspect your tracks for any signs of misalignment or damage.

- Use a track level tool to ensure your tracks are properly leveled, especially on curves and grades.

- For damaged sections, use track cutters to remove the affected area and replace it with new track.

- Ensure all rail joiners are secure and providing good electrical contact between track sections.

Rolling Stock Maintenance

Regular maintenance of your locomotives and rolling stock is essential for reliable operation:

- Check and tighten any loose screws on locomotives and cars.

- Inspect couplers for proper alignment and operation, replacing any damaged or worn components.

- Clean and lubricate locomotive gears and motors according to manufacturer recommendations.

- Test each piece of rolling stock regularly to ensure smooth rolling and proper tracking.

| Maintenance Task | Frequency | Tools Needed |

|---|---|---|

| Track Cleaning | Weekly | Track cleaning rubber, isopropyl alcohol |

| Wheel Cleaning | Monthly | Wheel cleaning brush, cotton swabs |

| Lubrication | Quarterly | Model train oil, fine-tipped applicator |

| Electrical System Check | Bi-annually | Multimeter, wire strippers |

| Track Alignment | Annually | Track level, track cutters |

Seasonal Maintenance Considerations

The changing seasons can affect your model railway, especially if it's located in an area subject to temperature and humidity fluctuations. Here are some seasonal maintenance tips to keep your layout in top condition year-round:

Spring

- Conduct a thorough cleaning of all tracks and rolling stock after the winter months.

- Check for any damage caused by cold temperatures or humidity changes.

- Inspect your layout for any signs of pest intrusion that may have occurred during the winter.

Summer

- Monitor humidity levels and use dehumidifiers if necessary to prevent warping of wooden components.

- Clean tracks more frequently, as dust tends to accumulate faster in warmer months.

- Check electrical connections for any signs of heat-related expansion or loosening.

Autumn

- Prepare your layout for cooler temperatures by checking heating and insulation in your train room.

- Clean fallen leaves or debris that may have found their way onto your layout.

- Lubricate moving parts to prepare for potential temperature-related contraction.

Winter

- Monitor indoor heating to prevent excessive dryness, which can affect wooden components.

- Check for any condensation issues that may arise due to temperature differences.

- Ensure proper ventilation to prevent mold growth in damp conditions.

Storage and Display

Proper storage and display of your model trains are crucial aspects of maintenance, especially for preserving rarely used or valuable pieces. Consider the following tips:

- Store locomotives and rolling stock in display cases to protect them from dust and accidental damage.

- Use acid-free tissue paper to wrap models when storing them for extended periods.

- Keep your storage area climate-controlled to prevent temperature and humidity fluctuations.

- Regularly dust and clean display areas to maintain a pristine appearance.

- Consider using UV-resistant display cases for valuable or rare models to prevent fading.

Expert Advice: Rotating Your Collection

Consider rotating the models on display in your layout. This not only keeps your scenery fresh and interesting but also ensures that all your models receive regular use and attention. Rotation helps distribute wear evenly across your collection and allows you to perform maintenance checks on pieces that might otherwise be overlooked. It's an excellent way to rediscover forgotten treasures in your collection and keep your enthusiasm for the hobby alive.

Troubleshooting Common Issues

Even with regular maintenance, you may encounter some common issues with your model railway. Here's how to diagnose and solve some frequent problems:

Erratic Train Movement

- Possible Cause: Dirty tracks or wheels

- Solution: Thoroughly clean both tracks and wheel surfaces

Locomotive Failure to Start

- Possible Cause: Poor electrical contact or motor issues

- Solution: Check wiring connections and clean motor brushes

Derailments

- Possible Cause: Misaligned tracks or wheel gauge issues

- Solution: Use a track gauge tool to check and adjust track alignment

Electrical Shorts

- Possible Cause: Crossed wires or metal debris on tracks

- Solution: Inspect wiring and thoroughly clean tracks

For more complex issues, don't hesitate to consult our FAQ page or reach out to our expert team for personalized advice.

Upgrading Your Maintenance Tools

As you become more experienced in model railway maintenance, you may want to invest in some advanced tools to make your maintenance tasks easier and more effective. Consider adding these items to your toolkit:

- Digital Multimeter: For precise electrical diagnostics

- Airbrush Cleaning Station: For thorough cleaning of delicate parts

- Ultrasonic Cleaner: Ideal for cleaning small, intricate components

- Precision Screwdriver Set: For working on tiny screws and fittings

- Magnifying Lamp: To help with detailed work on small parts

Explore our railway tools collection to find high-quality maintenance equipment that can elevate your model railway care routine.

A well-maintained model railway is a joy to operate and a testament to the hobbyist's dedication. Regular care not only ensures smooth operation but also deepens your connection to each miniature component of your layout.

Conclusion

Maintaining your model railway is an essential aspect of the hobby that ensures long-lasting enjoyment and smooth operation of your miniature world. By implementing regular cleaning routines, proper lubrication practices, and addressing both basic and advanced maintenance needs, you can significantly enhance the performance and longevity of your layout. Remember, consistent care not only prevents issues but also deepens your understanding and appreciation of your model railway.

At Hearns Hobbies, we're committed to supporting your model railway journey with quality products, expert advice, and a wide range of resources. Whether you're a beginner or a seasoned enthusiast, we're here to help you keep your trains running smoothly for years to come. Don't hesitate to explore our extensive collection of maintenance tools and supplies, and reach out to our team for personalized guidance on your model railway care routine.

Ready to Elevate Your Model Railway Maintenance?

Explore our comprehensive range of maintenance tools and supplies to keep your layout in top condition. From basic cleaning essentials to advanced diagnostic equipment, we have everything you need to ensure your model railway runs smoothly for years to come.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments