Choosing the Right Glue for Your Model Kit Type

Master the art of model assembly with the perfect adhesive

The success of any model kit build lies in the details, and perhaps none is more crucial than selecting the right adhesive. Whether you're crafting a magnificent plastic aircraft, assembling an intricate wooden ship, or detailing a resin miniature, your choice of glue can dramatically influence the final result. At Hearns Hobbies, we're dedicated to helping you achieve professional-quality results with our comprehensive range of specialised adhesives.

| Model Kit Adhesives at a Glance | |

|---|---|

| Adhesive Categories | Plastic cement, CA glue, epoxy, wood glue, speciality adhesives |

| Key Applications | Plastic kits, wooden models, resin figures, metal models, foam crafts |

| Essential Features | Bond strength, drying time, precision application, material compatibility |

| Safety Considerations | Proper ventilation, skin protection, storage requirements, working temperature |

Understanding Model Adhesives

The foundation of successful model building lies in understanding how different adhesives interact with various materials. Modern model kits encompass a wide range of materials, from traditional polystyrene plastics to sophisticated resin components, each demanding specific adhesive properties for optimal results. The science behind model adhesives involves chemical reactions that create bonds between surfaces, and choosing the right type can mean the difference between a sturdy, professional-looking model and a fragile assembly.

Types of Glue for Model Kits

Each type of model adhesive serves a specific purpose in the hobbyist's toolkit. Plastic cement, the most commonly used adhesive, works by actually melting the plastic surfaces together, creating a chemical weld that's stronger than the original material. Meanwhile, cyanoacrylate (CA) adhesives offer rapid bonding capabilities crucial for small parts and repairs, whilst wood glues provide the perfect solution for wooden model kits with their superior penetration and long-term durability.

| Adhesive Type | Primary Uses | Working Time |

|---|---|---|

| Plastic Cement | Polystyrene kits, detailed assemblies | 30-60 seconds |

| CA Glue (Super Glue) | Multi-material bonding, quick fixes | 5-15 seconds |

| Epoxy | Heavy-duty bonds, gap filling | 5-30 minutes |

Pro Tip:

For optimal results with plastic cement, apply the adhesive to both surfaces and allow it to sit for 10-15 seconds before joining. This ensures proper chemical activation and creates a stronger bond.

Best Glue for Different Model Types

Selecting the appropriate adhesive for your specific model type is crucial for achieving professional results. For plastic model kits, liquid cement provides the strongest possible bond by creating a chemical weld between parts. Wooden models require specialised wood glues that penetrate the fibres whilst maintaining flexibility, preventing brittleness over time.

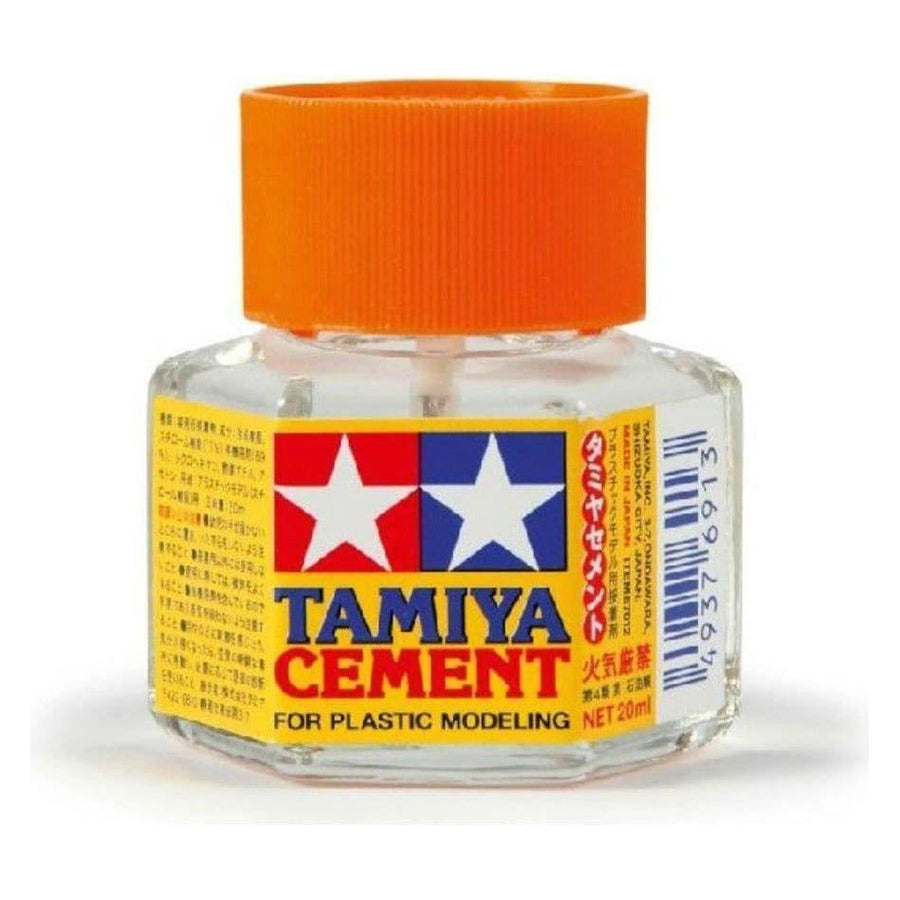

Professional-grade plastic cement for precise model assembly

For complex builds involving multiple materials, consider using a combination of adhesives. CA glue works brilliantly for attaching metal or resin parts to plastic models, whilst epoxy provides exceptional strength for larger structural components. When working with clear parts, such as windows or canopies, specialised clear plastic cement prevents fogging and maintains transparency.

Tips for Applying Model Glue Effectively

Mastering the art of adhesive application is crucial for achieving professional results in model building. Proper technique not only ensures stronger bonds but also maintains the aesthetic appeal of your finished model. When working with plastic cement or CA glue, precision is paramount to prevent unsightly excess adhesive that can mar your model's surface.

Professional application tools for precise adhesive control

Essential Application Techniques

- Surface Preparation: Ensure all surfaces are clean, dry, and free from oils or dust before applying adhesive.

- Test Fitting: Always dry-fit parts before applying glue to ensure proper alignment and identify potential challenges.

- Controlled Application: Use precision applicators or toothpicks for detailed work, applying glue sparingly to prevent overflow.

- Working Time Management: Be mindful of different adhesives' working times to achieve optimal bonding strength.

- Proper Ventilation: Work in a well-ventilated area, particularly when using solvent-based adhesives.

Common Mistakes and How to Avoid Them

Even experienced modellers can encounter challenges with adhesives. Understanding common pitfalls helps prevent costly mistakes and ensures better results. When working with wood glue or epoxy, proper clamping techniques and patience during curing are essential for achieving strong, lasting bonds.

| Common Mistake | Prevention Technique |

|---|---|

| Excessive Adhesive Application | Use precision applicators and apply thin layers |

| Insufficient Curing Time | Follow manufacturer's recommended curing times strictly |

| Improper Material Matching | Verify adhesive compatibility with model materials |

Recommended Glues and Accessories

Selecting the right combination of adhesives and accessories elevates your model-building experience. Our curated selection at Hearns Hobbies includes essential tools for precise application and professional results. From specialised decal solutions to advanced CA accelerators, we offer everything needed for successful model assembly.

Essential Toolkit:

- Precision applicator bottles for controlled dispensing

- Micro-tip extensions for detailed work

- Quick-release clamps for securing parts

- Adhesive accelerators for rapid curing

- Cotton swabs and cleaning solutions for excess removal

For specialised applications, consider our range of structural adhesives and plastic cements designed for specific model types. Each product in our collection has been carefully selected to meet the exacting standards of both beginner and experienced model builders.

Frequently Asked Questions

How do I choose between plastic cement and CA glue?

The choice depends on your materials. Plastic cement is specifically designed for polystyrene plastic kits, creating a chemical weld that's stronger than the original material. CA glue is more versatile and works with multiple materials, making it ideal for mixed-media models or quick repairs.

Why isn't my plastic cement creating a strong bond?

Poor bonding with plastic cement usually occurs due to:

- Insufficient surface preparation or cleaning

- Using cement on non-compatible plastics

- Not allowing enough contact time before joining parts

- Applying too much or too little cement

- Working with expired or contaminated adhesive

How can I prevent fogging on clear parts?

To protect clear parts when gluing:

- Use specialized clear plastic cement designed for transparent components

- Apply adhesive sparingly and only to the joining surfaces

- Ensure proper ventilation during application

- Avoid getting regular plastic cement near clear parts

- Consider using CA glue with precision applicators for better control

What's the best way to fix gaps in wooden models?

For wooden model gaps, use a combination of wood glue and fine sawdust to create a natural-looking filler. For larger gaps, consider using epoxy with proper sanding after curing.

Conclusion

Selecting and properly using the right adhesive is fundamental to successful model building. Whether you're working with plastic kits, wooden models, or mixed media projects, understanding your adhesive options and application techniques will significantly impact your results.

Remember that patience and precision are your greatest allies in model building. Take time to prepare surfaces properly, use the right adhesive for your materials, and allow adequate curing time. With proper technique and quality products from our comprehensive range at Hearns Hobbies, you'll be well-equipped to tackle any modeling project with confidence.

Final Thoughts:

The journey to mastering model assembly is ongoing, but with the right adhesives and techniques, every project becomes an opportunity to refine your skills. Keep experimenting, learning, and most importantly, enjoy the rewarding process of bringing your models to life with professional-quality results.

is here! Shop now, pay later in 4 easy installments

is here! Shop now, pay later in 4 easy installments